Top 10 Corrugated Box Printing Machines and Their Applications in 2025

In the fast-paced world of packaging, choosing the right printing machine is crucial for producing high-quality, durable, and visually appealing corrugated boxes. From high-volume shipping cartons to premium retail packaging, manufacturers rely on specialized equipment to meet diverse production needs.

This comprehensive guide highlights the top 10 corrugated box printing machines in 2025, including flexographic, offset, digital, gravure, screen, pad, laser, letterpress, rotogravure, and inkjet technologies. Each type is explained in detail, covering its ideal applications, advantages, and suitability for different packaging scenarios. Whether you are seeking efficiency, precision, or customization, this guide will help you select the right printing solution for your business.

- What is a Corrugated Box Printing Machine? Understanding Its Role in Packaging

- Top 10 Printing Machines for Corrugated Boxes and Their Key Applications

- Flexographic (Flexo) Printing Machines—Ideal for High-Volume Corrugated Packaging

- Offset printing machines—precision printing for labels and high-end packaging

- Digital Printing Machines—Flexible, Short-Run, and Custom Packaging

- Gravure Printing Machines—Large-Area, High-Color Packaging

- Screen Printing Machines—Decorative and Specialty Packaging

- Pad Printing Machines—Precision Printing on Irregular Surfaces

- Laser Printing and Engraving Machines—Secure and High-Precision Marking

- Letterpress Printing Machines—Traditional and Premium Packaging

- Rotogravure/Transfer Printing Machines—Efficient Long-Run Production

- Inkjet Printing Machines—Fast and Flexible Short-Run Printing

- Comparison Table of the Top 10 Corrugated Box Printing Machines

- How to Choose the Right Printing Machine from the Top 10 Options

- Custom Flexographic Printing and Die-Cutting Solutions for Corrugated Boxes

- Conclusion: Selecting the Best Printing Machine from the Top 10 for Your Packaging Business

What is a Corrugated Box Printing Machine? Understanding Its Role in Packaging

A corrugated box printing machine is a specialized piece of equipment designed to print logos, text, and graphics on corrugated boards used for shipping and retail packaging. These machines ensure that packaging is functional and visually appealing, combining durability with branding opportunities.

Many modern machines integrate multiple functions, such as die-cutting, slotting, and folding, which streamlines production processes. These machines allow manufacturers to produce high-quality packaging efficiently by combining precision, speed, and flexibility, thus meeting diverse client demands.

Top 10 Printing Machines for Corrugated Boxes and Their Key Applications

Flexographic (Flexo) Printing Machines—Ideal for High-Volume Corrugated Packaging

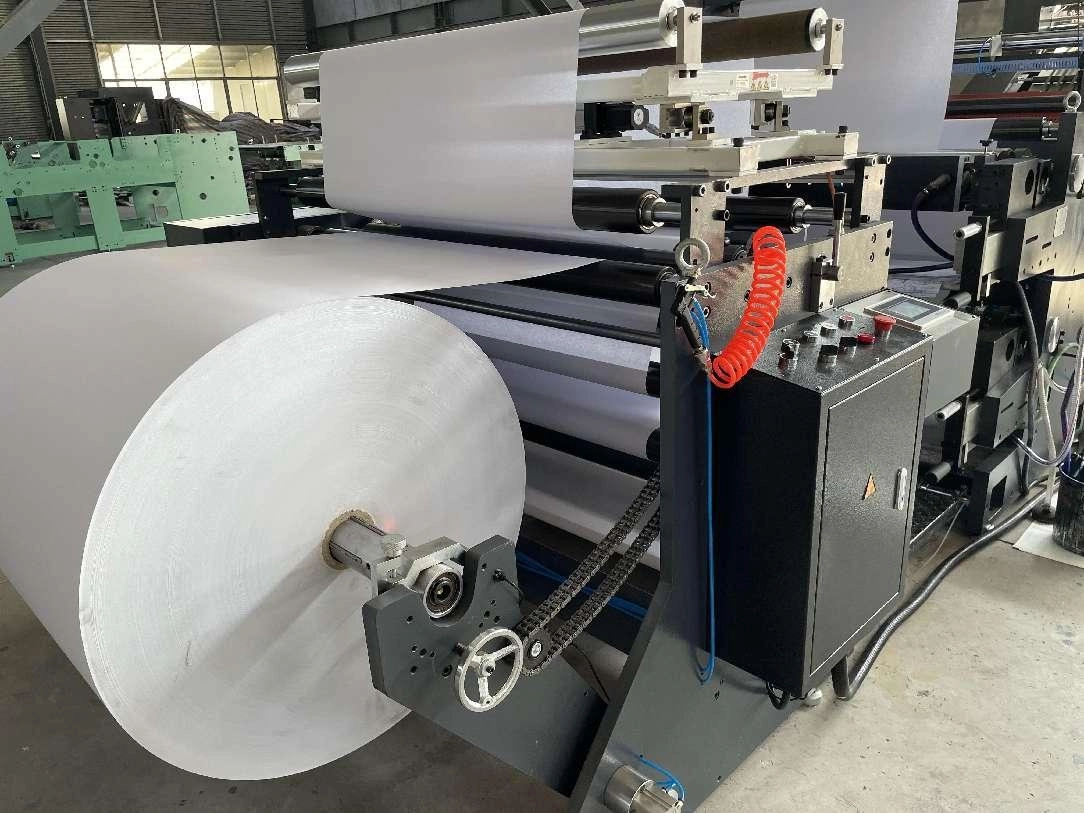

Flexo printing machines are perfect for high-speed production on corrugated boards. They use flexible plates and quick-drying inks to handle uneven surfaces while maintaining consistent print quality. Integrated systems often combine printing, slotting, and die-cutting in a single line, improving workflow and reducing manual handling.

They are especially suitable for bulk packaging, such as shipping boxes and display cartons. Flexo printing balances high-volume output with quality and versatility, enabling moderate customization without slowing production.

At Shinko, we offer advanced solutions like the Super Alpha Flexo Printer series, featuring full servo drives and high-speed capacity for efficient, precise printing. Designed for ease of operation and minimal waste, these machines ensure consistent quality for large-scale packaging. Learn more on our product page.

Offset printing machines—precision printing for labels and high-end packaging

Offset printing machines provide detailed, high-resolution graphics with consistent color reproduction. Using a plate-to-blanket transfer system, they deliver sharp images suitable for labels, folding cartons, and premium packaging.

This method excels for intricate designs, logos, and fine text. When combined with finishing techniques like varnishing or laminating, offset machines create professional, high-quality packaging that enhances product presentation and brand perception.

Digital Printing Machines—Flexible, Short-Run, and Custom Packaging

These machines allow for quick, plate-free printing, making them ideal for small batches, prototypes, and personalized packaging. They enable quick design changes and rapid turnaround times, making them perfect for responsive production needs.

They are widely used for e-commerce packaging, promotional items, and custom gift boxes. Digital printing delivers vibrant, precise graphics and supports variable data printing, such as QR codes or serial numbers. This allows for personalized, eye-catching packaging.

Gravure Printing Machines—Large-Area, High-Color Packaging

Gravure printing machines are designed for high-volume, large-format printing. Engraved cylinders transfer dense, vibrant inks to films, plastics, and continuous roll materials to produce consistent, high-quality results.

These machines are widely used for food, beverage, and consumer goods packaging. Gravure printing is ideal for long runs, ensuring a uniform appearance and color accuracy across thousands of meters of material.

Screen Printing Machines—Decorative and Specialty Packaging

Screen printing machines apply ink through a mesh stencil to create decorative effects such as embossing, foil stamping, and textured finishes. These machines are ideal for luxury packaging, cosmetics boxes, and gift packaging.

Screen printing can accommodate unusual shapes and surfaces, creating visually and tactilely appealing packaging. This method adds perceived value to products, making them stand out on shelves and enhancing brand recognition in high-end markets.

Pad Printing Machines—Precision Printing on Irregular Surfaces

Pad printing machines use silicone pads to transfer ink onto uneven or curved surfaces. This makes them suitable for small packaging components, promotional items, and specialty designs.

The method ensures accurate reproduction of logos, designs, or patterns on complex shapes. Manufacturers can maintain consistent quality across different product types while achieving high precision in small or detailed printing areas.

Laser Printing and Engraving Machines—Secure and High-Precision Marking

Laser printing and engraving machines create precise marks, barcodes, QR codes, and security features. The laser beam etches directly onto the material without contact, ensuring accuracy and permanence.

These machines are ideal for luxury, pharmaceutical, and electronics packaging. Laser technology enables intricate designs, secure markings, and minimal material waste, resulting in clean, efficient, and highly reliable production.

Letterpress Printing Machines—Traditional and Premium Packaging

Letterpress printing creates a tactile, embossed effect on packaging, giving it a handcrafted, premium appearance. This technique is often used for boutique gift boxes, luxury packaging, and high-end products.

It allows for deep impressions and textured finishes, which are often combined with specialty inks or foils. Letterpress printing enhances product presentation, providing a unique, visually striking solution that elevates brand perception.

Rotogravure/Transfer Printing Machines—Efficient Long-Run Production

Rotogravure printing machines are ideal for continuous, long-run production. Engraved cylinders precisely transfer ink to the substrate, delivering uniform results over extended print runs.

These machines are commonly used for high-volume packaging of food, beverages, and consumer goods. Rotogravure printing ensures consistent quality, durability, and high-speed production, making it an efficient choice for mass packaging operations.

Inkjet Printing Machines—Fast and Flexible Short-Run Printing

Inkjet printing machines provide rapid, plate-free printing for prototypes, small batches, and personalized orders. They produce high-resolution graphics and variable data with minimal setup time.

These machines are ideal for short-run packaging, sample production, and customized items. Their flexibility enables manufacturers to respond quickly to changing orders while maintaining quality, making them ideal for dynamic packaging needs.

Comparison Table of the Top 10 Corrugated Box Printing Machines

| Printing Machine Type | Suitable Applications | Key Advantages | Cost Range |

|---|---|---|---|

| Flexographic (Flexo) | Corrugated packaging | High speed, integrated die-cutting/slotting | >10,000 sheets |

| Offset | High-end paper packaging, labels | High precision, detailed graphics | >30,000 sheets |

| Digital | Short-run, personalized packaging | Plate-free, fast response | <5,000 sheets |

| Gravure | Films, plastics, long-roll packaging | High color gamut, large-area printing | >500,000 sheets |

| Screen | Specialty substrates, decorative | Foil stamping, matte finish, 3D effects | 10,000–50,000 sheets |

| Pad | Small area, irregular surfaces | Flexible, high precision for spot printing | <10,000 sheets |

| Laser | Security marks, high-precision logos | High precision, complex designs | <5,000 sheets |

| Letterpress | Luxury gift boxes | Traditional tactile feel, vintage style | >30,000 sheets |

| Rotogravure / Transfer | Long-roll, mass production | Efficient, stable, suitable for large runs | >100,000 sheets |

| Inkjet | Short-run, prototyping | Plate-free, flexible, rapid response | <5,000 sheets |

How to Choose the Right Printing Machine from the Top 10 Options

The right machine for the job depends on production volume, substrate type, and design complexity. High-volume manufacturers often rely on flexo or rotogravure machines, while digital or inkjet printers are better suited for short runs or custom packaging.

Additional capabilities, such as die-cutting, embossing, and slotting, should be considered for complex designs. Selecting the correct machine ensures an efficient workflow, consistent quality, and optimal cost management, helping manufacturers reliably meet client expectations.

Custom Flexographic Printing and Die-Cutting Solutions for Corrugated Boxes

These custom solutions integrate flexographic printing with die-cutting and slotting to streamline production and reduce manual handling. These systems allow manufacturers to efficiently produce retail packaging, display boxes, and specialty products while maintaining consistent quality.

Using tailored solutions helps manufacturers reduce waste, improve throughput, and create durable, visually appealing packaging that meets client specifications. Integrated systems provide the flexibility to create customized designs without slowing production.

Conclusion: Selecting the Best Printing Machine from the Top 10 for Your Packaging Business

Selecting the right corrugated box printing machine enhances productivity, ensures consistent quality, and elevates the visual appeal of packaging. Manufacturers can optimize operations and deliver reliable, attractive packaging solutions that strengthen brand presence by considering production scale, substrate type, and desired printing effects.

Recommended for you

The Ultimate Guide to Choosing a Flexo Folder Gluer for High-Speed Carton Production

How to Optimize Your Flexo Printing Machine for Maximum Speed and Zero Defects

What is Flexographic Printing? The Ultimate Technical Guide & Process Breakdown (2025)

Top 10 Best Flexo Printer Manufacturers (2026): Reviews & Buying Guide

How to Select the Best Flexo Printing Press Manufacturer: A Data-Driven Checklist (2026 Edition)

Shipping

Do you offer international shipping for your machines?

Yes, we offer international shipping and can handle all necessary customs documentation.

Do you provide installation services upon delivery?

Yes, we offer on-site installation and training services to ensure your machine is set up correctly.

Product

Do your machines support automated quality control checks?

Yes, our machines can be equipped with automated quality control systems to ensure consistent production quality.

Industry Solutions

Do you offer solutions for environmentally friendly packaging?

Yes, our machines can produce cartons from recyclable and biodegradable materials, supporting sustainable packaging solutions.

How can your machines improve my production workflow?

By automating carton production, our machines streamline your workflow, increase output, and reduce downtime.

Leave a message

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2025 Keshenglong & SHINKO All Rights Reserved.

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine