What is Flexographic Printing? The Ultimate Technical Guide & Process Breakdown (2025)

Flexographic printing is a modern, versatile printing technique that industry professionals refer to as flexography, and it is used extensively for packaging and labeling needs. Modern manufacturing has embraced flexography as a core technology because of its high-speed production combined with efficiency and its ability to handle a variety of materials. This guide provides a comprehensive examination of flexo printing and why companies around the world are choosing it for their operations.

- Introduction: The Evolution of Modern Flexography

- Why It Is the Dominant Technology

- A Brief History: From 'Aniline' to HD

- How the Flexographic Printing Process Works (Step-by-Step)

- 1. Pre-press & Plate Making

- 2. Plate Mounting

- 3. Ink Metering

- 4. Image Transfer (The "Kiss" Impression)

- 5. Drying & Curing

- Core Machine Components: A Technical Deep Dive

- The Anilox Roller: The Heart of the Press

- Doctor Blade Systems

- Impression Cylinders

- Automated Inking Systems

- Flexo Ink Systems: Water-Based vs. Solvent vs. UV

- Water-Based Inks

- Solvent-Based Inks

- UV and EB (Electron Beam) Inks

- Regulatory Compliance

- Critical Comparison: Flexo vs. Offset vs. Digital

- Flexo vs. Offset

- Flexo vs. Digital

- Substrate Versatility

- Common Flexo Defects and Troubleshooting

- Halo Effect

- Gear Marks (Banding)

- Pinholing

- Dot Gain

- Conclusion

- FAQs

In the rapidly evolving world of industrial manufacturing, the flexographic printing process stands as the undisputed champion of the packaging industry. From the cereal box on your breakfast table to the shrink sleeve on your vitamin bottle, flexography (or "flexo") is responsible for the vast majority of printed packaging worldwide.

As we move through 2025, modern flexography has transcended its reputation for simple line work to rival gravure and offset in quality, thanks to High-Definition (HD) technologies and precision engineering. This guide provides a comprehensive technical breakdown of flexographic printing, designed for engineers, print managers, and packaging professionals seeking to optimize their production lines.

Introduction: The Evolution of Modern Flexography

Flexographic printing is a form of rotary relief printing. Simply defined, it is a method where a flexible plate—typically made of photopolymer—applies ink directly to a substrate. It operates on a similar principle to a rubber stamp but runs at incredibly high speeds (often exceeding 2,000 feet per minute) on a continuous web of material.

Why It Is the Dominant Technology

The packaging industry relies on flexography because of its unique duality: versatility and speed. Unlike other print methods that are restricted to flat paper, flexo can print on non-porous substrates like plastic films, metallic foils, and cellophane, as well as rough surfaces like corrugated cardboard.

According to the Flexographic Technical Association (FTA), flexography continues to hold the largest market share in package printing due to its ability to handle long runs cost-effectively while maintaining color consistency across difficult substrates.

A Brief History: From 'Aniline' to HD

Historically, this process was known as "Aniline printing" due to the aniline oil-based dyes used in the early 20th century. However, these inks were toxic and banned for food packaging. In the 1950s, the process was rebranded as flexography, coinciding with the introduction of safe, fast-drying inks. Today, with the advent of digital plate-making and laser-engraved anilox rolls, we have entered the era of HD Flexo, capable of reproducing complex gradients and high-resolution images that were once impossible.

How the Flexographic Printing Process Works (Step-by-Step)

Understanding the flexographic printing process requires a look at the sequential mechanics of the press. It is a continuous loop of ink metering, transfer, and drying.

1. Pre-press & Plate Making

The process begins with image preparation. Modern flexo relies heavily on Computer-to-Plate (CTP) technology.

· Analog Plates: Used film negatives and UV exposure.

· Digital (CTP) Plates: A laser ablates a black mask layer on the photopolymer plate, which is then exposed to UV light. This creates sharper dots and steeper shoulders on the relief image, reducing dot gain during the print run.

2. Plate Mounting

Once the plate is processed, it is mounted onto a plate cylinder. This step is critical for registration (ensuring colors align perfectly). Operators use "stickyback" tape—a double-sided adhesive foam. The density of this foam matters; harder tape is used for solids, while softer tape is preferred for fine process work to absorb vibration.

3. Ink Metering

The ink is pumped into an ink pan or a clearer chamber system. A fountain roll (or metering roll) picks up the ink and transfers it to the anilox roller. The anilox roller is the heart of the ink density control, metering the exact amount of ink required.

4. Image Transfer (The "Kiss" Impression)

The anilox roller transfers a thin film of ink onto the raised parts of the flexible plate. The plate cylinder then rotates and presses against the substrate (paper, film, or foil), which is supported by the impression cylinder.

The goal is a "kiss impression"—the lightest possible pressure required to transfer the image. Excessive pressure leads to image distortion (halo effects).

5. Drying & Curing

Between each color station (Cyan, Magenta, Yellow, Black, etc.), the substrate passes through inter-station dryers.

· Hot Air/Infrared: Used for water-based and solvent inks to evaporate the carrier vehicle.

· UV LED: Used for UV inks, instantly curing the photopolymer ink into a solid plastic state.

Core Machine Components: A Technical Deep Dive

To master flexography, one must understand the interaction between the machine's critical components. The quality of the print is often determined by the precision of the anilox roller technical details and the efficiency of the doctor blade systems.

The Anilox Roller: The Heart of the Press

The anilox roller is a ceramic-coated steel cylinder engraved with millions of microscopic cells. Two key metrics define an anilox roll:

1. Cell Volume (BCM): Billions of Cubic Microns per square inch. This determines the amount of ink delivered. Higher BCM is used for bold solid colors; lower BCM is used for fine details.

2. Line Screen (LPI): Cells per inch. For high-quality HD flexo, printers use high LPI rolls (800–1200 LPI) to support fine plate dots.

Doctor Blade Systems

To ensure the anilox roll delivers a consistent film of ink, a doctor blade shaves off the excess ink from the roller's surface, leaving ink only inside the cells.

· Chambered Doctor Blade Systems: The industry standard for modern presses. It creates a closed loop where ink is pumped in and doctored off simultaneously. This prevents solvent evaporation and keeps viscosity consistent.

· Blade Material: Steel, plastic, or coated composite blades are chosen based on the abrasiveness of the ink and the anilox ceramic.

Impression Cylinders

The impression cylinder creates the backing pressure. On wide-web CI (Central Impression) presses, a single large drum supports the substrate for all print stations. This ensures superior registration stability for stretchable materials like polyethylene (PE) film.

Automated Inking Systems

Modern presses feature automated viscosity and pH controls (for water-based inks). If the ink becomes too thick (high viscosity), color density increases, and drying issues occur. Automation adds solvent or water in real-time to maintain stability.

Flexo Ink Systems: Water-Based vs. Solvent vs. UV

Selecting the correct flexo ink types is dependent on the substrate and the end-use of the product (e.g., food safety vs. outdoor durability).

Water-Based Inks

· Primary Use: Corrugated board (boxes), paper packaging, and increasingly on films.

· Pros: Low VOC emissions, environmentally friendly, easy cleanup.

· Cons: Requires high energy to dry; lower gloss compared to UV.

Solvent-Based Inks

· Primary Use: Flexible packaging (plastic food bags, shopping bags).

· Pros: Excellent wetting on non-porous plastic films; very fast drying (evaporation).

· Cons: High VOC emissions; requires solvent recovery systems to meet EPA regulations.

UV and EB (Electron Beam) Inks

· Primary Use: High-end labels, cosmetic packaging, and shrink sleeves.

· Pros: Inks stay liquid until exposed to UV light, allowing for easy stops and starts. High gloss and chemical resistance.

· Cons: More expensive; safety concerns regarding uncured photoinitiators.

Regulatory Compliance

For food packaging, ink migration is a critical safety concern. Manufacturers must strictly adhere to FDA food contact guidelines to ensure that components of the ink do not migrate through the packaging and contaminate the food product.

Critical Comparison: Flexo vs. Offset vs. Digital

When choosing a print technology, the debate often centers on flexo vs offset printing or the rising challenge of digital.

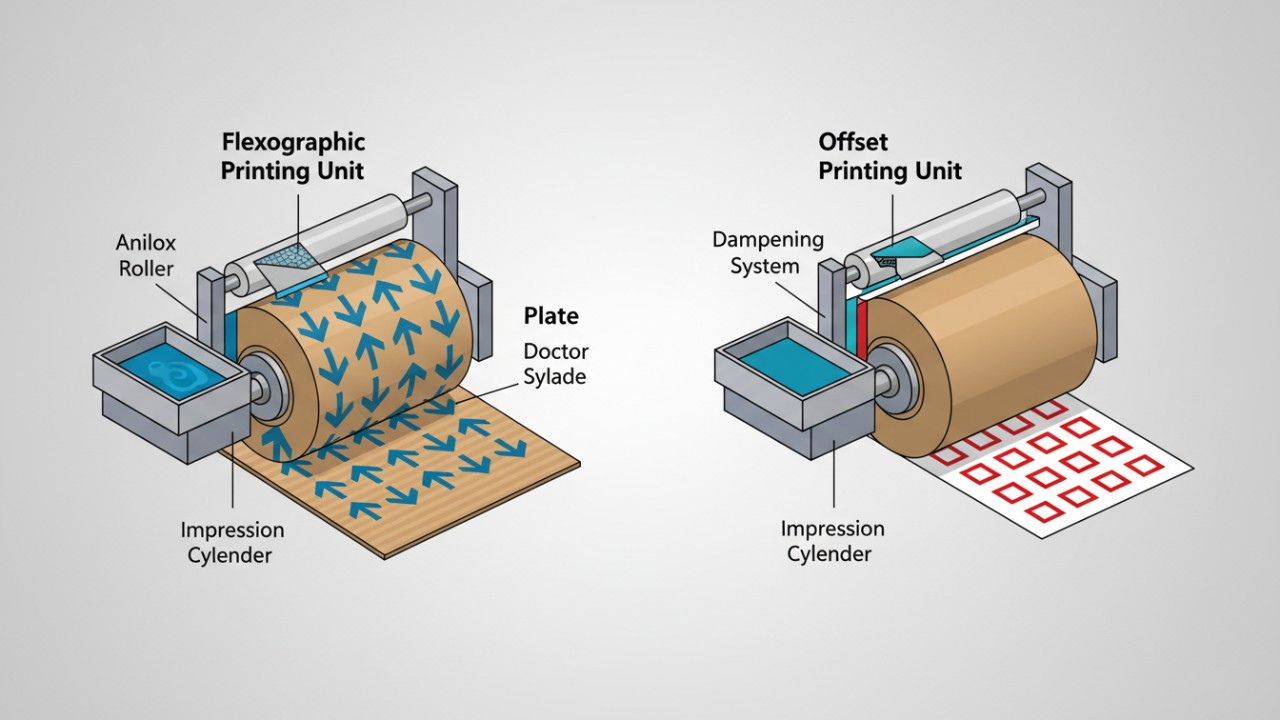

Flexo vs. Offset

· Plate Technology: Offset uses flat metal plates and requires water/ink balance. Flexo uses raised relief plates.

· Substrates: Offset dominates the publication and high-quality paper folding carton market. Flexo dominates flexible films, foils, and corrugated board.

· Cost Dynamics: Offset plates are cheaper, but flexo is more efficient for continuous roll-to-roll finishing (die-cutting inline).

· Quality: Offset generally holds a slight edge in ultra-fine vignettes, but HD Flexo has largely closed this gap.

Flexo vs. Digital

· Breakeven Point: Digital (Inkjet/hp Indigo) requires zero plate costs, making it cheaper for short runs (e.g., < 2,000 units).

· Speed: Flexo is significantly faster. For runs exceeding 10,000 units, flexo is the only economically viable option.

· Pantone Matching: Flexo utilizes spot color inks (Pantone) physically mixed for perfection. Digital simulates Pantones using CMYK, which can result in slight variances.

Substrate Versatility

The Flexible Packaging Association highlights that the growth of flexible pouches is driving the flexo market. Flexo's ability to "kiss" print allows it to handle uneven surfaces (like the flutes of a cardboard box) without crushing the material—something offset cannot do.

Common Flexo Defects and Troubleshooting

Even with advanced machinery, defects occur. Recognizing them is key to maintaining quality.

Halo Effect

· Appearance: A double edge or ring around printed elements (text or dots).

· Cause: Excessive pressure between the plate and the impression cylinder (over-impression).

· Solution: Back off the pressure until the "kiss" setting is achieved.

Gear Marks (Banding)

· Appearance: Horizontal light and dark bands across the web.

· Cause: Mechanical vibration or worn gears. It can also be caused by the pitch of the gear not matching the plate thickness perfectly.

· Solution: Inspect drive gears, check bearing conditions, or switch to servo-driven (gearless) technology.

Pinholing

· Appearance: Tiny unprinted specks in solid color areas.

· Cause: Ink failing to wet out the substrate properly (surface tension issue) or dirty anilox cells.

· Solution: Check substrate Dyne level (corona treatment), adjust ink viscosity, or clean the anilox roll.

Dot Gain

· Appearance: Images look darker or "muddy"; fine dots grow in size during transfer.

· Cause: Physical pressure or incorrect mounting tape (too hard).

· Solution: Use a "cutback" curve in pre-press to compensate for the gain or use softer mounting tape.

Conclusion

Flexographic printing remains the most versatile and cost-effective solution for high-volume packaging, balancing blistering production speeds with increasing print quality. By mastering the technical interaction between the anilox roller, doctor blade, and the various flexo ink types, manufacturers can achieve offset-quality results at a fraction of the cost.

Whether you are printing on corrugated board or sophisticated flexible film, choosing the right machine configuration—and maintaining precise control over the process variables—is critical to maximizing ROI and minimizing waste in 2025.

FAQs

What is the main difference between Flexo and Offset printing?

The main difference lies in the plate and ink transfer method. Flexo uses flexible relief plates and can print on almost any substrate (plastic, metallic film, corrugated), while Offset uses flat metal plates and is primarily used for high-quality paper printing. Flexo is generally more cost-effective for packaging and long runs.

Is flexographic printing suitable for food packaging?

Yes, flexography is the industry standard for food packaging. It utilizes food-safe water-based and UV-curable inks that comply with FDA regulations. Modern presses also use 'indirect food contact' safe drying methods to prevent ink migration.

How long do flexo printing plates last?

High-quality photopolymer flexo plates are very durable and can last for millions of impressions if stored and handled correctly. Their longevity makes flexo highly economical for repeat orders compared to digital printing.

If you have further questions or require a professional solution, please feel free to contact us at any time.

Recommended for you

How to Optimize Your Flexo Printing Machine for Maximum Speed and Zero Defects

Top 10 Best Flexo Printer Manufacturers (2026): Reviews & Buying Guide

How to Select the Best Flexo Printing Press Manufacturer: A Data-Driven Checklist (2026 Edition)

High-Efficiency Flexo Press Solutions: A Complete Guide to Optimizing Your Packaging Production

Mastering the Flexo Printer: The 2026 Complete Guide to High-Speed Production Efficiency

Shipping

What should I do if my machine arrives damaged?

If your machine arrives damaged, please contact our customer service immediately to arrange for repairs or replacement.

What is the estimated delivery time for your machines?

Delivery times vary based on location and order size, but we typically estimate 4-6 weeks for delivery.

Industry Solutions

Can your machines handle high-volume production demands?

Yes, our machines are designed for high-volume production, ensuring reliable and efficient operation.

What is the lifespan of your folding carton machines?

With proper maintenance, our machines are built to last for many years, providing long-term value for your investment.

Product

What materials are compatible with your folding carton machines?

Our machines are compatible with a wide range of materials including cardboard, corrugated board, and paperboard.

Leave a message

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2025 Keshenglong & SHINKO All Rights Reserved.

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine