Mastering Flexo Printing in 2026: Machines, Processes, and Packaging Solutions

A comprehensive guide to flexographic printing machines for 2026. Covers operational processes, key components like anilox rollers, machine types, and future trends in automation and sustainability. Features expert insights on Keshenglong&Shinko's advanced corrugated packaging solutions.

- What is a Flexo Printing Machine?

- Key Takeaways: Flexo Printing at a Glance

- The Evolution and History of Flexographic Printing

- How a Flexo Printing Machine Works: The End-to-End Process

- Understanding the Core Components of a Flexo Printing Machine

- Types of Flexo Printing Machines: Choosing the Right Press

- Key Benefits of Flexo Printing for Modern Manufacturing

- Flexo Printing Applications: From Labels to Corrugated Boxes

- Advanced Features & Innovations in Flexo Technology (2026+ Trends)

- Expert Tips for Maximizing Flexo Machine Performance

- Calculating Your ROI: Investing in a Flexo Printing Machine

- Common Challenges in Flexo Printing and How to Overcome Them

- Choosing the Best Flexo Printing Machine Manufacturer

- Conclusion: Flexible, Efficient, and Sustainable – The Future of Flexo Printing

- FAQs: Flexo Printing Machines

- References

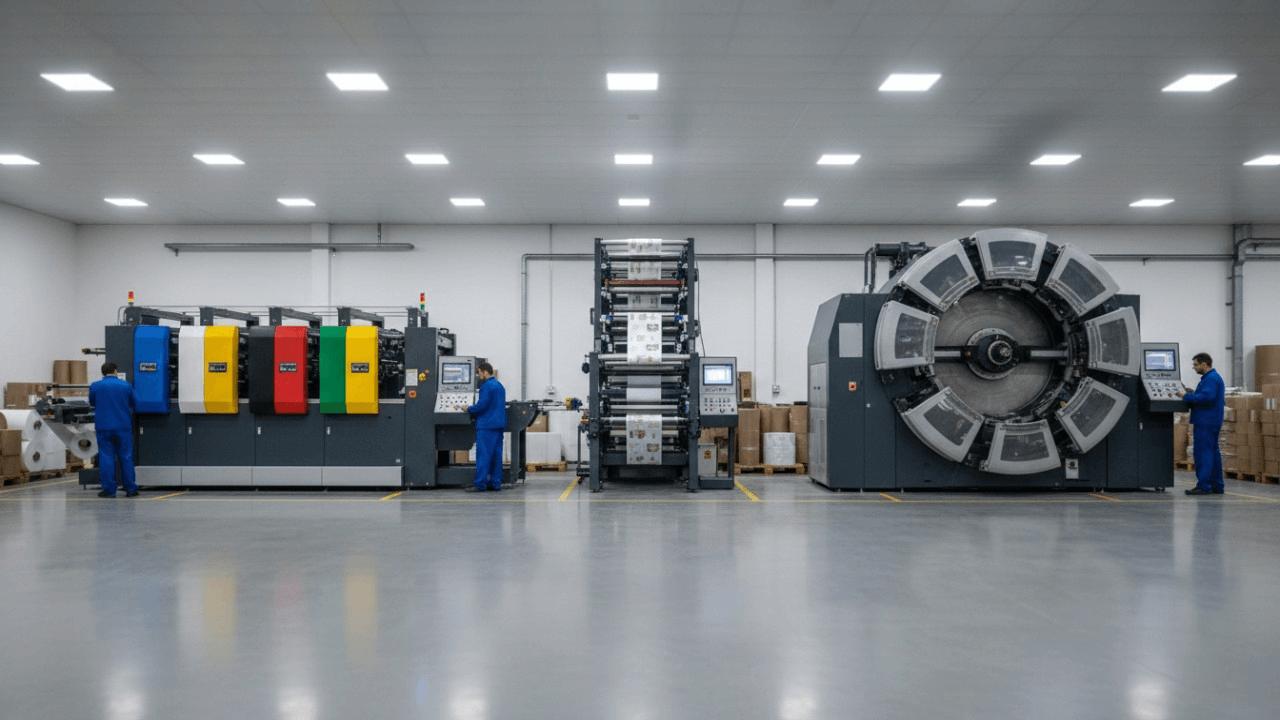

What is a Flexo Printing Machine?

A flexographic printing machine is an industrial rotary press that uses flexible relief plates to transfer ink directly onto various substrates, including paper, plastic, and corrugated board.

Unlike offset printing, which uses flat plates, the flexo printing process relies on a raised image area (similar to a rubber stamp) to deliver high-speed, cost-effective results for packaging. This versatility allows manufacturers to print on both porous and non-porous materials, making it the dominant technology for the global packaging market, which Smithers reports hit a value of $230.5 billion in 2024.

Key Takeaways: Flexo Printing at a Glance

Flexo printing is the industry standard for high-volume packaging production due to its speed, versatility, and adaptability to modern automation.

While digital printing grabs headlines for short runs, flexographic printing machine technology remains the workhorse for long-run scalability. Modern presses now integrate AI and robotics, blurring the lines between traditional mechanical operation and smart manufacturing.

· Definition: A rotary printing method using flexible plates for direct ink transfer.

· Main Advantages: Superior speed, lower cost per unit for long runs, and substrate versatility.

· Key Applications: Flexible packaging, labels, corrugated carton printing machine operations, and folding cartons.

· Evolution: Transitioning from simple mechanical presses to AI-driven, fully automated systems.

· Future (2026+): Heavy focus on sustainability (water-based inks) and hybrid digital-flexo workflows.

The Evolution and History of Flexographic Printing

Flexography evolved from simple "aniline printing" in the 19th century to today's high-definition, laser-engraved photopolymer plate technology.

Originally used for simple designs on paper bags, the technology saw a massive leap with the introduction of the central impression cylinder and UV-curable inks. Today, manufacturers like Keshenglong&Shinko represent the pinnacle of this evolution, merging Chinese manufacturing scale with Japanese precision engineering to serve over 70 countries since 1995.

· Late 1800s: Originates as aniline printing using rubber stamps.

· 1950s: Rebranded as "flexography" with the advent of safer inks and improved plates.

· 2000s: Introduction of digital plate-making (CTP) and gearless drive technology.

· 2017 Milestone: Keshenglong merges with Japan Shinko, establishing a Japanese R&D center to integrate top-tier components and standards.

How a Flexo Printing Machine Works: The End-to-End Process

The flexo printing process involves feeding a substrate through a series of rotary stations where ink is metered, transferred to a plate, and impressed onto the material.

This continuous web process allows for inline finishing, meaning raw material enters one end and a finished, cut, and folded product exits the other. This efficiency is critical for packaging printing solutions where time-to-market is tight.

1. Pre-press Phase: Digital artwork is converted into a relief plate (photopolymer or rubber) via laser engraving.

2. Ink Metering: The ink is pumped into a chamber where a doctor blade wipes excess ink from the anilox roller.

3. Image Transfer: The anilox roller function is to carry a precise microscopic layer of ink to the raised parts of the plate cylinder.

4. Impression: The plate cylinder rotates against the substrate, pressed by the impression cylinder, transferring the image.

5. Drying & Finishing: The ink is dried instantly (UV, hot air, or IR), and the substrate moves to die-cutting or folding stations.

Understanding the Core Components of a Flexo Printing Machine

A flexo press consists of five main sections: the unwind station, infeed, printing stations, drying systems, and the rewind or finishing unit.

Each component must work in perfect synchronization to maintain registration accuracy. Advanced machines, such as the "6+1" high-precision series from Keshenglong&Shinko, utilize imported parts from Japan to ensure these components operate with micron-level tolerance.

· Unwind/Rewind Units: Controls the roll of material, maintaining precise tension to prevent wrinkling.

· Anilox Roller: A ceramic or steel cylinder engraved with millions of tiny cells; it determines the exact volume of ink delivered.

· Doctor Blade System: A blade that scrapes excess ink off the anilox roller to ensure a consistent ink film thickness.

· Plate Cylinder: The cylinder where the flexible printing plate is mounted via double-sided tape or magnetic sleeves.

· Drying Systems: Inter-station dryers prevent ink smearing between colors, crucial for high-speed runs.

· Control Panel: The brain of the machine. Keshenglong&Shinko machines feature computerized controls managed by experienced Japanese technicians for optimal setup.

Types of Flexo Printing Machines: Choosing the Right Press

Flexo presses are categorized by their deck configuration: Central Impression (CI), Stack, and In-line presses, each serving different market needs.

Selecting the right flexo press types depends on your substrate and print quality requirements. For example, the corrugated industry relies heavily on robust in-line systems.

· Central Impression (CI) Press: All print stations are arranged around a single large steel cylinder.

o Best for: Flexible films and thin plastics requiring tight registration.

· In-line Press: Stations are arranged in a straight horizontal line.

o Best for: Corrugated carton printing machine applications, folding cartons, and labels. This is a specialty of Keshenglong&Shinko, whose slotting die-cutting machines offer high-speed precision.

· Stack Press: Stations are stacked vertically.

o Best for: Simple, multi-color jobs where floor space is limited.

· Wide Web vs. Narrow Web: Narrow web is used for labels; wide web is used for flexible packaging and bags.

Key Benefits of Flexo Printing for Modern Manufacturing

Flexo printing offers the lowest cost per unit for long production runs while maintaining high speeds and compatibility with eco-friendly inks.

Data from Grand View Research indicates the market is growing at a CAGR of roughly 4.1-5.8%, driven largely by these efficiency gains. Unlike digital flexo printing hybrids that are still costly for massive volumes, traditional flexo remains the king of ROI for big brands.

· Cost-Effectiveness: Durable plates can last for millions of impressions, reducing long-term consumable costs.

· Substrate Freedom: Prints on everything from rough corrugated board to glossy metallic foils.

· Speed: Modern presses can exceed 600 meters per minute.

· Sustainable Options: Supports water-based inks, reducing VOC emissions compared to solvent-based rotogravure.

· Integrated Finishing: Can cut, crease, and fold inline, reducing labor and handling steps.

Flexo Printing Applications: From Labels to Corrugated Boxes

Flexography is the dominant technology for packaging, covering everything from self-adhesive labels and flexible food pouches to heavy-duty shipping boxes.

The ability to print on non-porous surfaces makes it indispensable for the food sector. Keshenglong&Shinko has capitalized on this by specializing in jumbo-size flexo printing slotting die-cutting machines, essential for the booming e-commerce shipping box market.

· Corrugated Cartons: Shipping boxes and retail-ready displays (Keshenglong's core expertise).

· Flexible Packaging: Chip bags, candy wrappers, and stand-up pouches.

· Labels: Beverage labels, shampoo bottles, and shrink sleeves.

· Sanitary Products: Printing on non-woven fabrics for diapers and hygiene items.

· Wallpaper and Flooring: Printing patterns on large rolls of decorative material.

Advanced Features & Innovations in Flexo Technology (2026+ Trends)

The future of flexo lies in "Smart Flexo," combining automated pressure settings, AI-driven defect detection, and hybrid digital integration.

As we look toward 2026, flexo printing technology is becoming less reliant on operator skill and more on machine intelligence. Smithers data predicts a shift toward expanded color gamut (ECG) printing, which uses a fixed 7-color palette to simulate spot colors, reducing ink waste.

· Hybrid Presses: Machines that combine flexo stations for whites/varnishes with digital inkjet bars for variable data.

· AI Registration: Cameras that automatically adjust plate alignment in real-time, reducing setup waste.

· Japanese Standard Automation: Companies like Keshenglong&Shinko are integrating rigorous quality control systems derived from their Japan Shinko merger to meet these high-tech demands.

· Sustainable Inks: A massive shift toward water-washable plates and bio-renewable inks to meet global environmental regulations.

Expert Tips for Maximizing Flexo Machine Performance

Consistent maintenance of the anilox rollers and precise viscosity control of the ink are the two most critical factors for high-quality flexo output.

Neglecting these variables leads to the most common defects, such as "dot gain" (where images look muddy) or "skip out" (missing ink).

1. Protect the Anilox: Clean rollers immediately after runs; dried ink in the microscopic cells ruins print volume accuracy.

2. Monitor Viscosity: Use automatic viscosity controls to keep ink consistency stable throughout the run.

3. Plate Storage: Store photopolymer plates in cool, dark environments to prevent cracking or warping.

4. Regular Calibration: Schedule quarterly audits of the machine's mechanical gears and impression settings, a service emphasized by Keshenglong&Shinko's support teams.

5. Operator Training: Invest in training staff on the latest "Gearless" drive technologies to prevent handling errors.

Calculating Your ROI: Investing in a Flexo Printing Machine

Return on Investment (ROI) in flexo is driven by speed and material savings; high-volume shops often see ROI in under 24 months due to lower per-unit costs.

While the upfront cost of a machine (like a 6-color computerized press) is significant, the operational savings compared to digital printing for runs over 10,000 units are substantial.

· Reduced Waste: Automated setup systems cut make-ready waste by up to 50%.

· Labor Savings: Inline die-cutting means one operator can handle printing and finishing simultaneously.

· Energy Efficiency: New LED-UV curing systems use significantly less power than traditional mercury lamps.

· Market Expansion: Capability to handle complex packaging printing solutions opens doors to premium brand clients.

Common Challenges in Flexo Printing and How to Overcome Them

The most frequent challenges in flexo are registration errors, halo effects (ink spreading), and consistent color matching across different substrates.

These issues often stem from mechanical wear or improper setup. Leveraging high-precision machinery, such as Keshenglong&Shinko's "6+1" precision series, mitigates these mechanical variables.

· Halo Effect: Cause: Too much pressure between plate and substrate. Fix: Adjust impression settings to "kiss" pressure.

· Gear Marks: Cause: Worn gears or vibration. Fix: Upgrade to servo-driven (gearless) technology.

· Pinholing: Cause: Ink not wetting the substrate. Fix: Adjust ink viscosity or treat the substrate surface (corona treatment).

· Dirty Print: Cause: Dried ink on the plate. Fix: Use auto-wash systems and check drying speed.

Choosing the Best Flexo Printing Machine Manufacturer

When selecting a manufacturer, prioritize companies that offer a blend of technological innovation, robust after-sales support, and proven global reliability.

Look for manufacturers that combine high-end engineering with cost-effective production bases. Keshenglong&Shinko is a prime example of this hybrid advantage. Founded in 1995 and merged with Japan Shinko in 2017, they offer machines built to Japanese quality standards but manufactured in Guangzhou. With exports to over 70 countries and on-site testing by Japanese technicians, they provide a trusted solution for flexo machine components and complete lines.

· Heritage: Look for decades of experience (e.g., founded pre-2000).

· Technology Transfer: capabilities (e.g., R&D centers in Japan or Europe).

· Global Footprint: Ability to service machines internationally.

· Product Range: Availability of specific solutions like high-speed slotting or jumbo presses.

Conclusion: Flexible, Efficient, and Sustainable – The Future of Flexo Printing

Flexographic printing machines remain the backbone of modern packaging, offering speed, cost-efficiency, and substrate versatility. From 19th-century rubber-stamp printing to today’s AI-driven, hybrid systems, the technology has continually evolved to meet global market demands.

Investing in advanced flexo presses, such as Keshenglong & Shinko’s high-precision series, ensures consistent quality, efficiency, and sustainability through water-based inks and energy-saving systems. With automation and smart controls, flexo printing is not just a method—it is a strategic asset enabling high ROI and competitive advantage across labels, flexible packaging, and corrugated boxes.

FAQs: Flexo Printing Machines

Q1: What is a flexographic printing machine?

A flexographic printing machine is an industrial rotary press that uses flexible relief plates to transfer ink directly onto various substrates, including paper, plastic, and corrugated board. It is widely used for high-volume packaging production.

Q2: What are the main advantages of flexo printing?

Flexo printing offers high speed, cost efficiency for long runs, substrate versatility, and compatibility with eco-friendly inks. Modern presses also integrate automation and inline finishing, reducing labor and waste.

Q3: What types of flexo printing machines exist?

The main types are:

-

Central Impression (CI) Press: Best for flexible films and thin plastics.

-

In-line Press: Ideal for corrugated cartons, folding cartons, and labels.

-

Stack Press: Suited for multi-color jobs with limited floor space.

Q4: What materials can be printed with flexo machines?

Flexo presses can print on paper, cardboard, plastics, metallic foils, films, and non-woven fabrics, making them ideal for labels, flexible packaging, corrugated boxes, and sanitary products.

Q5: How does a flexo printing machine work?

The process involves feeding a substrate through printing stations where ink is metered via an anilox roller, transferred to a flexible plate, and pressed onto the material. Drying and finishing steps complete the process inline.

Q6: How do I maximize ROI with a flexo press?

Invest in high-precision machinery, maintain anilox rollers, control ink viscosity, and provide operator training. Inline finishing and automated setup reduce waste and labor, enabling ROI often within 1–2 years.

Q7: What are common challenges in flexo printing?

Frequent issues include registration errors, halo effects, pinholing, and inconsistent color. Proper machine calibration, automated registration, and substrate treatment can minimize defects.

References

Wikipedia – History of Printing

Smithers: The Future of Flexographic Printing to 2029

Recommended for you

How to Optimize Your Flexo Printing Machine for Maximum Speed and Zero Defects

What is Flexographic Printing? The Ultimate Technical Guide & Process Breakdown (2025)

Top 10 Best Flexo Printer Manufacturers (2026): Reviews & Buying Guide

How to Select the Best Flexo Printing Press Manufacturer: A Data-Driven Checklist (2026 Edition)

High-Efficiency Flexo Press Solutions: A Complete Guide to Optimizing Your Packaging Production

Industry Solutions

Can your machines be integrated with digital printing technology?

Yes, our machines are compatible with digital printing systems for custom, high-quality printing on cartons.

What kind of technical support do you offer for industry applications?

We provide comprehensive technical support, including installation, maintenance, and troubleshooting services.

Product

How can I integrate your machines into my existing production line?

Our technical team can assist with integrating our machines into your current production setup, ensuring a seamless operation.

Shipping

How are your machines packaged for safe transportation?

Our machines are securely packaged using high-quality materials to prevent damage during transit.

What should I do if my machine arrives damaged?

If your machine arrives damaged, please contact our customer service immediately to arrange for repairs or replacement.

Leave a message

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2025 Keshenglong & SHINKO All Rights Reserved.

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine