Litho vs Flexo: Understanding the differences and why flexo is the future of packaging

There are two printing techniques that bring different characteristics to the industry: litho and flexo. For the packaging industry, flexographic printing is the main game changer, offering superior efficiency along with versatility and sustainability, while litho printing retains its excellence in producing highly detailed output. This blog will explore the flexo printing workflow and how it contrasts with litho printing, as well as assess how flexo is transforming packaging market applications. The information presented in this guide will prove essential for manufacturers as well as designers and those interested in the packaging printing methods of tomorrow.

- Introduction to litho and flexo printing

- What is lithographic printing?

- What is flexographic printing?

- Key differences between litho and flexo printing

- Printing process and technology

- Print quality and resolution

- Cost and efficiency

- Applications of litho and flexo printing

- When to choose litho

- When to choose flexo

- Why flexo is the future of packaging

- Advancements in flexo technology

- Environmental benefits of flexo printing

- Market trends driving flexo adoption

- Conclusion

Introduction to litho and flexo printing

Print production technologies have changed dramatically over time, as each method serves specific needs. Litho and flexo are the two basic printing techniques used today. Flexo printing has become the industry leader in packaging production. Our analysis will examine the differences between these methods, describe the two Flexo printing processes in detail, and establish why Flexo is the market leader for packaging applications.

What is lithographic printing?

Traditional lithographic printing, also known as litho or offset printing, has been a widely used printing method for many decades. The process is based on the incompatibility of water and oil substances.

Flat aluminum plates are chemically treated during processing to create image-bearing areas and ink-repelling non-image areas. The image areas naturally attract ink, while the non-image areas attract water. After the plate is inked, the rubber blanket receives the image and transfers it to the printing surface, usually paper.

The process provides accurate image production with exceptional clarity of detail, making it ideal for magazine and brochure production as well as poster development. The use of water-based and oil-based inks in this printing process creates difficulties for certain materials that require packaging, as it restricts their appropriate use.

What is flexographic printing?

The flexible modern printing process known as flexography or flexo printing has now become widely used throughout the packaging industry. The difference between litho and flexo is that flexo uses flexible relief plates made from rubber or photopolymer materials.

In flexo, flexible plates receive fast-drying, low-viscosity inks that are applied to their raised surfaces. The system deposits the ink mixture directly onto a variety of substrates, including paper and board, plastic films, and metal foils. High production speed and quality consistency are the result of this process, which achieves high efficiency rates.

High-volume flexible printing benefits from flexographic techniques, making it ideal for the production of packaging materials such as labels and corrugated boxes, as well as flexible plastic goods.

Key differences between litho and flexo printing

Choosing the right printing process requires a full understanding of the characteristics of litho and flexo printing. The main differences require detailed consideration.

Printing process and technology

Flat plates combined with difficult ink/water control in litho reduce production speeds and the range of materials that can be processed effectively. The use of raised plates together with fast-drying inks in flexo printing systems allows higher production speeds and superior substrate conformability.

Flexo has superior performance on plastic films because it can handle these non-porous materials that cause difficulties for litho printing. The choice of flexographic printing for packaging becomes favorable because of its characteristics.

Print quality and resolution

The famous characteristics of litho printing are both sharp resolution and the ability to work with complex detail in designs. Developments in flexo printing technology have improved plate materials and precision ink systems, narrowing the quality gap between flexo and litho.

Modern flexo printing produces results that meet litho standards while retaining the speed and efficiency required for high-volume packaging production.

Cost and efficiency

The use of litho printing remains the best choice for both affordable and high-quality marketing materials in short to medium runs. Diagnostic printing techniques are cost-effective for short to medium print runs, while flexo printing is more cost-effective for high-volume packaging production.

The sustainability goal of reducing environmental impact is supported by Flexo, as it allows for water-based and UV-curable inks that minimize waste.

Applications of litho and flexo printing

The separate litho and flexo printing technologies excel in different areas of production.

When to choose litho

Projects that require detailed visual elements along with vibrant color should be produced using litho printing methods for magazines, brochures, and posters. Short-run jobs will benefit from this option due to reduced makeready.

Because Flexo produces flexible packaging at higher speeds, it is better suited to materials that require durability and short runs.

When to choose flexo

Flexo printing is proving to be ideal for the production of labels, flexible packaging, and corrugated board throughout the packaging industry. The combination of wide material compatibility with affordable running costs makes Flexo an essential tool for packaging production companies.

Flexo is used in a wide range of applications, including food and beverage labels and pharmaceutical packaging, where durability and print consistency are required.

Why flexo is the future of packaging

The packaging industry is currently undergoing a transformation due to the constant pressure for greater efficiency and sustainability, as well as the need for customization. Flexo is the future of packaging because it offers key advantages that are driving its dominance in the industry.

Advancements in flexo technology

Flexo technology is being enhanced by digital plate imaging combined with better ink formulations, resulting in improved print quality with greater consistency. Flexo has become more competitive with litho and digital by offering equivalent resolution and color accuracy standards.

In addition, the development of hybrid printing systems that combine flexo with digital technologies has opened up new opportunities for personalization and short-run packaging.

Environmental benefits of flexo printing

Flexo is establishing itself as an ideal solution to address the sustainability issues affecting the packaging sector. The combination of water-based and UV-curable inks reduces VOC emissions, and the efficient use of materials reduces product waste.

The flexo printing process meets the demand for sustainable packaging options as it works well with recyclable and biodegradable substrates.

Market trends driving flexo adoption

The growth of online retailing has created additional market needs for strong, durable packaging that can withstand shipping procedures. Flexo's ability to produce strong, attractive packaging is perfectly suited to the needs of this market segment.

Flexo continues to grow in popularity as it meets the market need for customized and personalized packaging through efficient and adaptable printing solutions.

Conclusion

The choice between litho and flexo requires an assessment of both print quality and substrate capability, as well as production speed and overall cost. The need for detailed short runs indicates that litho should be the preferred option. For long runs, Flexo is the winner because it offers durability while being efficient and sustainable.

The future of the packaging industry will be based on flexo printing because of its ability to meet current market needs.

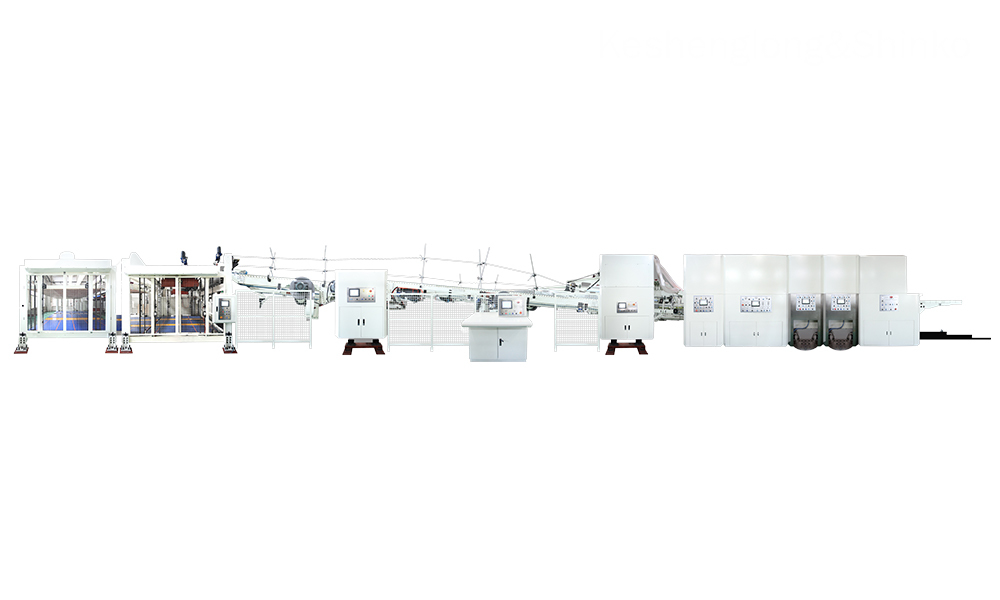

At Keshenglong & Shinko, we specialize in manufacturing state-of-the-art flexographic printing machines designed to meet the needs of the packaging industry. Our machines combine cutting-edge technology with unmatched reliability, helping companies achieve superior print quality and efficiency.

If you're looking to improve your packaging production, contact us and browse our range of flexo printing machines to find out more about how we can help your business.

Recommended for you

How to Optimize Your Flexo Printing Machine for Maximum Speed and Zero Defects

What is Flexographic Printing? The Ultimate Technical Guide & Process Breakdown (2025)

Top 10 Best Flexo Printer Manufacturers (2026): Reviews & Buying Guide

How to Select the Best Flexo Printing Press Manufacturer: A Data-Driven Checklist (2026 Edition)

High-Efficiency Flexo Press Solutions: A Complete Guide to Optimizing Your Packaging Production

Shipping

How are your machines packaged for safe transportation?

Our machines are securely packaged using high-quality materials to prevent damage during transit.

What is the estimated delivery time for your machines?

Delivery times vary based on location and order size, but we typically estimate 4-6 weeks for delivery.

What are the shipping costs for your folding carton machines?

Shipping costs depend on the destination, machine size, and shipping method. Contact us for a detailed quote.

Industry Solutions

What kind of technical support do you offer for industry applications?

We provide comprehensive technical support, including installation, maintenance, and troubleshooting services.

Product

Are there safety features integrated into your machines?

Yes, our machines come equipped with multiple safety features including emergency stop buttons and safety guards.

Leave a message

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2025 Keshenglong & SHINKO All Rights Reserved.

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine