How is printing done on corrugated boxes?

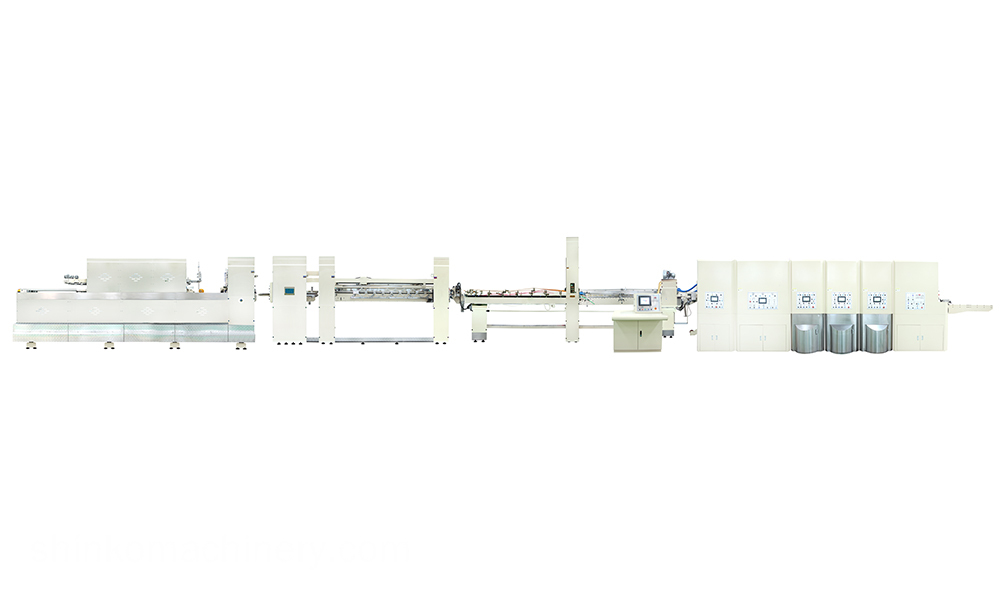

Discover how Keshenglong & Shinko utilizes advanced flexographic printing techniques to produce high-quality prints on corrugated boxes. Our cutting-edge technology ensures vibrant colors and precise graphics, enhancing your brand's visual appeal. Trust us for efficient and sustainable printing solutions that meet your business needs. Experience superior printing quality with Keshenglong&Shinko's expertise in the packaging industry.

- 1. Flexographic Printing (Flexo Printing)

- How It Works:

- Advantages:

- Limitations:

- 2. Lithographic Printing (Offset Printing)

- How It Works:

- Advantages:

- Limitations:

- 3. Digital Printing

- How It Works:

- Advantages:

- Limitations:

- 4. Screen Printing

- How It Works:

- Advantages:

- Limitations:

- 5. Rotogravure Printing

- How It Works:

- Advantages:

- Limitations:

- 6. Inkjet Printing

- How It Works:

- Advantages:

- Limitations:

- The process of branding and marketing and conveying important information cannot be complete without having your company logo or brand name printed on corrugated boxes. Most of the corrugated boxes are printed uniquely since the corrugated cardboard they are made of is comparatively rougher than paper. Corrugated boxes can be printed using several techniques, and each method delivers varied results as regards quality, cost- effectiveness and speed. Below is an overview of the most common printing methods used:

1. Flexographic Printing (Flexo Printing)

It can be used with most types of substrate and can be combined with any other form of printing; however, the equipment tends to be expensive.

Overview: Flexographic printing is used widely in the printing of corrugated boxes to meet the arising demand in the market. It employs elastic relief plates and is cited for high throughput production. Flexo printing may be carried on a single face as well as on both faces of the corrugated cardboard.

How It Works:

Flexible photopolymer plates mounted on revolving cylinders are used in flexographic presses. Ink is used to make prints on the raised features of the plate, with the corrugated material coming into contact with these features to obtain the picture. Flexographic printing mainly employs water-based or solvent-based inks, meaning that although the cost is relatively low for large runs, it is perfect for large runs.

Advantages:

High Speed: Great for high use, for example, bags for manufactured goods.

Cost-effective: Besides, there are reduced initial costs and costs per run for large orders.

Versatility: Ability to print other not easily written surfaces, such as corrugated cardboard, plastics and any hard surface that does not allow writing.

Eco-Friendly: At times, employs water authenticity inks that have lesser negative effects on the environment.

Limitations:

Limited Detail: Flexo printing is good for simple designs and large fonts; however, geometrical patterns cause more problems than anyone would care to venture at present, and while having a fair portrayal of CMYK colors, it is not excellent when it comes to smooth transition.

Setup Time: The initial investment in flexography entails substantial time during printing, especially when using the technique for small volumes.

2. Lithographic Printing (Offset Printing)

Overview: Usually, lithographic printing, known as offset printing, is used for quality print jobs, but it is not much in use for corrugated boxes because the material is rough. Nevertheless, it is still used for printing on flat sheets of corrugated material (prior to the creation of the box itself.).

How It Works:

Offset printing employs a plate—normally, an aluminum one—to roll the ink onto a rubber cylinder, which in turn impacts it on the corrugated board.

As with most other plates, the design is engraved onto the plates, and the process employs the use of water ink to push the ink in the right areas or pull it away from others.

Advantages:

High-Quality Images: The main pull of offset printing is that the delivered images are detailed and have good color quality.

Smooth Finish: Great for attaining a high-quality image and fine lines, and lettering of logos and designs for companies.

Limitations:

Less cost-effective for short runs: Still, offset printing has a higher set-up cost, so it is not very preferable for small quantities or custom-sized boxes.

Not Ideal for Corrugated Texture: There is always a little blur in corrugated material because the surface of the material is somewhat coarse to print images.

3. Digital Printing

Overview: Digital printing is another more advanced way of printing on corrugated boxes that is done directly from a digital source. It is most useful in situations where smaller quantities are needed, if an individual order is required, or in the case of greeting card printings where many designs are produced but only a few of each design is sold.

How It Works:

Ink jet and laser are the most usual technologies used in digital printers to directly apply ink onto the corrugated board.

This process does not involve the use of plates or rollers, which makes it very suitable for short-run or on-demand production.

Advantages:

No setup costs: digital printing does not need plates or screens, which can be said to be cheaper when used for short productions.

Quick Turnaround: Digital printing is faster since there are not many processes that have to be followed before starting the production process.

Customization: especially suitable for printing numbered designs and numeric codes, serial numbers, or barcodes and individual packaging.

Limitations:

Quality May Vary: Indeed, digital printing can provide a high degree of quality, although it is slightly less sharp or intense than flexographic or lithographic printing, due to improper adhesion to uneven corrugated surfaces.

Cost for Large Runs: However, it is worthy to note that for large quantities, the cost tends to rise more than the other means of printing.

4. Screen Printing

Overview: As for the corrugated boxes, it is not common to use screen printing, although it was observed that it can print very big fonts or images. Known as screen printing, it entails filtering ink through a fabric whose structure includes small and overlapping holes on the corrugated box.

How It Works:

A stencil or screen is developed from the design; hence, ink is squeezed through the mesh to transfer the image on the box.

Each color means one visit to the screen, which can turn the process into a more time-consuming affair when the design is many-colored.

Advantages:

Durability: The kind of ink used with screen printing is thick and can endure, therefore suitable for outdoor or high-wear applications.

Vivid Colors: This is why screen printing works best when it comes to reproducing vivid, rich colours.

Limitations:

Labor-intensive: takes longer and is costlier for multi-color prints.

Not Ideal for Fine Detail: Screen printing is ideal in scenarios where the design used is big and simple and where logos have to be printed.

5. Rotogravure Printing

Overview: Rotogravure printing, also called gravure printing, is an intaglio process in which the image is engraved on to a rotary cylinder, which then impresses the ink on to the corrugated material. This method is most suitable for organizations that involve very high-frequency runs.

How It Works:

First, a cylinder is etched with the design to be printed, and it is filled with ink.

The redundant ink is removed, while the design carved on copper is stamped onto the material.

This method is used in large format printing, especially on corrugated sheets.

Advantages:

High-Speed Production: Ideal for uses where you intend to print high quantity documents at a low cost per page.

High-Quality Images: Suitable for fine picture and multiple hue graphics.

Durable Ink: For rotogravure, the ink used is usually of a higher quality than used in other forms of print.

Limitations:

High Setup Costs: Similarly to offset, gravure has high initial costs and is not effective for small lots ordered.

Expensive for Small Runs: Able to offer prices that are less per unit if your company regularly orders blank products, but not for small batches.

6. Inkjet Printing

Overview: Digital printing that is applied to corrugated boxes includes inkjet printing as a technique that employs inkjet nozzles to discharge ink directly onto the corrugated surface. This method is gradually finding its application in on-demand and variable data printing technologies.

How It Works:

This technique involves the spraying of ink through high-pressure nozzles to print the image or the text from original data.

The new generation of printers can accommodate variables; therefore, common applications include printing barcodes, serial numbers, and trademarks.

Advantages:

Customization: Specially suitable for printing small-patterned graphics, letters, barcodes, and other special messages.

No Setup Fees: Does not need a plate, making it less expensive for short routes and packaging projects that have individual designs.

Quick Production: They are capable of providing very short cycle times for either small or highly specific jobs.

Limitations:

Quality Control: The qualitative performance of a corrugating medium is however good, as an inkjet printing system can deliver high image qualities, but the corrugated material can alter the focus shape.

Speed for Large Runs: Finally, compared to other techniques for large-volume runs, inkjet printing is relatively slow.

However, the determination of the printing process of corrugated boxes will involve the following key factors: number of cartons, design, quality requirement and production need of the final application of the box. Flexography is the most frequently used and fastest technique for large production volumes, while digital printing is a quicker way to get a custom or small order production. Lithographic printing offers good-quality prints but is mostly used on flat surfaces, while screen printing offers excellent results for bolder prints that will last longer.

Each of the methods has its advantages and disadvantages, mainly based on the production requirements, cost, and the degree of sophistication of the box design wanted.

Recommended for you

How to Optimize Your Flexo Printing Machine for Maximum Speed and Zero Defects

What is Flexographic Printing? The Ultimate Technical Guide & Process Breakdown (2025)

Top 10 Best Flexo Printer Manufacturers (2026): Reviews & Buying Guide

How to Select the Best Flexo Printing Press Manufacturer: A Data-Driven Checklist (2026 Edition)

High-Efficiency Flexo Press Solutions: A Complete Guide to Optimizing Your Packaging Production

Industry Solutions

Do you offer customized solutions for unique production needs?

Yes, we work closely with clients to develop customized solutions that meet their specific production requirements.

How can your machines improve my production workflow?

By automating carton production, our machines streamline your workflow, increase output, and reduce downtime.

Product

Do your machines support automated quality control checks?

Yes, our machines can be equipped with automated quality control systems to ensure consistent production quality.

How do I troubleshoot common issues with the folding mechanism?

Common issues can often be resolved by checking the alignment of the folding plates and ensuring there is no debris obstructing the mechanism.

Shipping

What are the shipping costs for your folding carton machines?

Shipping costs depend on the destination, machine size, and shipping method. Contact us for a detailed quote.

Leave a message

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2025 Keshenglong & SHINKO All Rights Reserved.

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine