Top 10 Corrugated Box Making Machines 2026: Buyer's Guide & Reviews

Selecting the right corrugated box making machine requires balancing production volume with budget. While BHS and Bobst offer elite performance for massive outputs, manufacturers like Keshenglong/Shinko provide a compelling competitive advantage through Japanese-engineered precision at a more accessible entry point. Prioritize machines that offer local after-sales support and Industry 4.0 integration to future-proof your investment.

- Introduction: The Shift to Automated Packaging Lines

- The Evolution from Manual to Computerized High-Speed Lines

- Why "High Quality" Printing and Precision are Non-Negotiable

- How Choosing the Right Machine Impacts Your Plant's ROI

- Global Industry Giants (High-Volume Production)

- 1. BHS Corrugated

- 2. Fosber Group

- 3. BW Papersystems

- 4. Sun Automation

- Best High-Speed Flexo Printer Slotters (FFG)

- 5. Bobst FFG 8.20 EXPERTLINE

- 6. Keshenglong (Shinko)

- 7. Dongfang Precision

- Comparison Table: Speed vs. Setup Time vs. Cost

- Buyer's Guide: Critical Selection Criteria

- Understanding Flute Types and Compatibility

- ROI Calculation: Balancing Investment vs. Waste

- After-Sales Network

- Flexo vs. Offset: Choosing the Right Technology

- Used vs. New Equipment Market

- Risks of Buying Second-Hand Packaging Machinery

- Retrofitting Older Lines

- Depreciation Rates

- Conclusion

- FAQs

The corrugated packaging industry is currently undergoing a massive technological transformation. As we approach 2026, the demand for sustainable, sturdy, and high-graphic packaging has never been higher. For packaging plant owners and production managers, the machinery you select today will dictate your profitability for the next decade.

This guide provides an in-depth review of the top corrugated box making machine options available in the global market, analyzing the giants of the industry and the high-performance contenders that are redefining ROI.

Introduction: The Shift to Automated Packaging Lines

Gone are the days when manual setups and slow mechanical adjustments were acceptable in a competitive box plant. The modern landscape is defined by box plant automation and data-driven manufacturing.

The Evolution from Manual to Computerized High-Speed Lines

Historically, converting lines required significant downtime for setup changes. Operators had to manually adjust slotting knives and print cylinders. Today, the transition to fully servo-driven technology means that a high speed flexo folder gluer can switch orders in under two minutes. This evolution is not just about speed; it is about the integration of the entire plant ecosystem, from the corrugator wet end to the palletizer.

Why "High Quality" Printing and Precision are Non-Negotiable

In 2026, the "brown box" is no longer just a shipping container; it is a marketing tool. E-commerce has driven brands to demand high-graphic capabilities directly on corrugated board. This requires machinery capable of precise registration and managing complex colors without crushing the flutes. According to data from the AICC - The Independent Packaging Association, the trend towards high-graphic flexo printing is accelerating, forcing manufacturers to upgrade equipment to meet stricter quality control standards.

How Choosing the Right Machine Impacts Your Plant's ROI

The capital expenditure (CAPEX) for packaging machinery manufacturers is significant. However, the cost of the machine pales in comparison to the cost of operational inefficiency. A machine that runs 10% faster with 2% less waste can generate millions in additional revenue over its lifespan. The key lies in selecting a machine that balances speed, energy consumption, and maintenance costs.

Global Industry Giants (High-Volume Production)

When discussing the heavyweights of the industry—particularly for complete corrugator lines and massive output—four names consistently dominate the global market.

1. BHS Corrugated

The German Powerhouse.

BHS Corrugated is widely recognized as the market leader for complete corrugator lines. Based in Germany, they specialize in high-volume, continuous-run machinery. Their "Steady State" philosophy aims to keep machines running at maximum width and speed for the longest possible duration. For mega-plants producing millions of square meters of board monthly, a BHS line is often the gold standard for reliability and predictive maintenance integration.

2. Fosber Group

Italian Excellence in Control Systems.

Fosber has carved out a massive share of the market by focusing on the "Wet End" and highly intuitive control systems. Known for their "Pro/Line" series, Fosber machines are celebrated for being incredibly user-friendly and reliable. Their sync logic between the wet end and the dry end ensures minimal warp and waste. Fosber is often the preferred choice for plants that need high speed but also require frequent flute changes, where their fast order change capabilities shine.

3. BW Papersystems

Versatility for Diverse Needs.

A conglomeration of historic brands (including MarquipWardUnited), BW Papersystems offers one of the broadest portfolios in the industry. From sheeting to corrugating and finishing, they provide versatile solutions. They are particularly strong in the rotary die-cutting sector and offer robust machinery that can handle a wide variety of board grades, making them a favorite for independent box plants handling diverse product mixes.

4. Sun Automation

Innovation in Feeding and Printing.

Sun Automation is legendary for its "Suntronic" lead edge feeding technology, which revolutionized how warped board is handled in a converting machine. While they produce complete machines, their technological upgrades and printing units are often integrated to boost the performance of existing lines. They remain a top choice for retrofitting and high-precision feeding solutions.

Best High-Speed Flexo Printer Slotters (FFG)

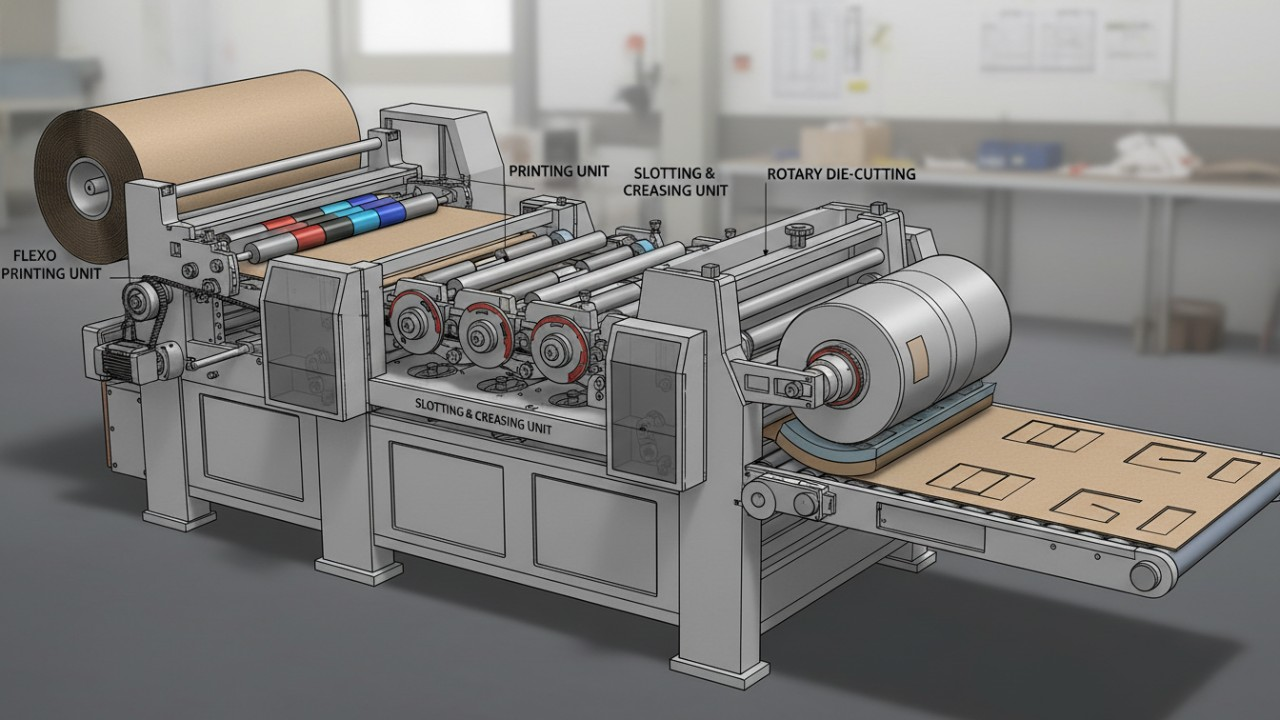

While the giants above handle the creation of the board, the profitability of a box plant often relies on the converting department. This is where the flexo slotting die cutting machine and Folder Gluers (FFGs) come into play.

5. Bobst FFG 8.20 EXPERTLINE

The Swiss Standard for Speed.

Bobst remains the benchmark for high-speed automated lines. The FFG 8.20 EXPERTLINE is a fully automated line that can produce up to 24,000 boxes per hour. It represents the pinnacle of box plant automation, featuring "Multifold" capabilities and ultra-quick setup times.

· Pros: Unmatched speed, high resale value, sophisticated quality control systems.

· Cons: Extremely high initial investment and expensive spare parts.

6. Keshenglong (Shinko)

The Best Price-Performance Ratio.

For 2026, Keshenglong (often partnering with Shinko technology) has emerged as the smartest buy for manufacturers who need elite performance without the "Swiss price tag." By combining Japanese R&D (Shinko) with the manufacturing efficiency of China (Keshenglong), they offer a high speed flexo folder gluer specifically designed for heavy-duty performance and precision.

· Why it wins: The KL-Shinko Super Alpha series rivals top-tier European machines in registration accuracy and speed (up to 375-400 sheets/min) but offers a significantly faster ROI due to lower capital costs. It is the ideal solution for plants expanding capacity that need reliable fixed-flexo units.

7. Dongfang Precision

Reliable Mid-Range Solutions.

Dongfang is a massive player in the Asian market and has expanded globally with great success. Their machines, such as the Apstar series, are workhorses. They offer reliable bottom-printing and top-printing solutions. While they may lack some of the ultra-refined IoT (Internet of Things) features of a Bobst, they are incredibly durable and easy to maintain, making them a staple in mid-sized box plants.

Comparison Table: Speed vs. Setup Time vs. Cost

|

Manufacturer |

Model Class |

Max Speed (Sheets/Min) |

Setup Time (Avg) |

Cost Tier |

Best Application |

|

Bobst |

FFG 8.20 |

400+ (24k/hr) |

< 2 Mins |

$$$$$ |

Ultra-High Volume, Standard Boxes |

|

Keshenglong |

Shinko Super Alpha |

350 - 375 |

2-3 Mins |

$$$ |

High Mix, High Quality, Fast ROI |

|

Dongfang |

Apstar HG2 |

250 - 300 |

4-5 Mins |

$$ |

Reliable General Production |

|

BHS |

Corrugator Line |

400 m/min |

Continuous |

$$$$$+ |

Board Manufacturing (Not Converting) |

Buyer's Guide: Critical Selection Criteria

Choosing a corrugated box making machine is complex. Here are the technical criteria you must evaluate.

Understanding Flute Types and Compatibility

Not all machines handle all flutes equally. Micro-flutes (E, F) require extremely precise crushing control (caliper control) to avoid destroying the structural integrity of the box. Conversely, heavy-duty double-wall (BC or AC flute) requires robust slotting shafts.

For a detailed understanding of standard corrugated designations, you can refer to the standards set by the European Federation of Corrugated Board Manufacturers (FEFCO), which outlines the global codes used for box design. Ensure your machine's vacuum transfer system is rated for the specific flutes you intend to run.

ROI Calculation: Balancing Investment vs. Waste

Don't look at the price tag; look at the "Cost per Box."

· Waste Reduction: A machine with a smart registration system that reduces setup waste by just 3 sheets per order can save $50,000+ annually in a high-turnover plant.

· Energy: Servo-driven machines consume less power than older gear-driven models.

After-Sales Network

Geography matters. If your plant is in the US or Europe, buying a machine from a manufacturer with no local service hub is a disaster waiting to happen.

· Bobst/BHS: Excellent global coverage.

· Keshenglong/Dongfang: Have established strong agent networks in North America and Europe to counter this concern. Always ask: "Where is the nearest spare parts warehouse?"

Flexo vs. Offset: Choosing the Right Technology

For most corrugated boxes, Flexography is the standard. It utilizes flexible relief plates and is ideal for rough surfaces like corrugated board. For a deeper technical dive, see the Flexography process definition to understand why it differs from Offset Lithography.

· Choose Flexo (Post-print): For shipping boxes, RSCs, and trays where speed and cost are priorities.

· Choose Offset (Litho-lam): When you need photo-realistic cosmetic boxes (though High-Quality Flexo is rapidly closing this gap).

Used vs. New Equipment Market

Risks of Buying Second-Hand Packaging Machinery

The used market is flooded with machines, but caveat emptor. The biggest risk with a used flexo slotting die cutting machine is the wear on the side frames and gears. If the main frame is not perfectly square due to years of vibration, the machine will never hold registration, regardless of how many new electronics you install.

Retrofitting Older Lines

A popular trend in 2026 is retrofitting. This involves taking a sturdy mechanical iron frame (like an old Ward or Langston) and stripping it of its old electrics. Companies like Sun Automation or independent integrators install new servo drives and computerized HMIs. This can be 40% cheaper than a new machine, but it does not increase the maximum mechanical speed of the unit.

Depreciation Rates

Top-tier brands like Bobst and BHS hold their value incredibly well. You can often resell a 10-year-old Bobst FFG for 50% of its original value. Budget models, however, depreciate faster. The "sweet spot" for many buyers is the Keshenglong/Shinko tier, where the initial cost is lower, reducing the financial risk of depreciation while still providing a modern, automated experience.

Conclusion

Selecting the right corrugated box making machine in 2026 requires balancing production volume with budget constraints.

For massive, continuous output where capital is abundant, BHS (for corrugators) and Bobst (for converting) remain the elite choices offering standard-setting performance. However, for the vast majority of independent box plants looking to maximize profitability, manufacturers like Keshenglong (Shinko) provide a compelling competitive advantage. They offer Japanese-engineered precision at a more accessible entry point, allowing for a faster ROI.

Ultimately, prioritize packaging machinery manufacturers that offer strong local after-sales support and Industry 4.0 integration to future-proof your investment. Automation is no longer a luxury; it is the baseline for survival.

FAQs

What is the price range for a high-speed flexo slotting machine?

Prices vary wildly based on automation levels. Entry-level semi-auto machines may start around $50,000, while fully computerized high-speed lines from top brands like Bobst or Keshenglong can range from $300,000 to over $2 million depending on the number of print units and die-cutting features.

What is the difference between BHS and Fosber machines?

Both are industry leaders. BHS Corrugated is often cited for having the widest range of complete wet-end to dry-end solutions and high-volume dominance. Fosber is renowned for its user-friendly control systems, reliability, and excellent sync with various dry-end equipment, often being a preferred choice for mid-to-high volume plants focusing on quick changeovers.

How do I calculate the ROI for a new box making machine?

To calculate ROI, factor in the reduction of waste (scrap rate), increase in speed (sheets per minute), and labor savings (automation). Compare these operational savings against the total cost of ownership (Machine Cost + Installation + Maintenance + Energy). A high-efficiency machine often pays for itself in 2-3 years through waste reduction alone.

If you have further questions or require a professional proposal, please feel free to contact us at any time.

Flexo Printer vs Digital Press: Which Is Best for Your Line?

Wholesale flexo printer slotter machine for corrugated box manufacturer and supplier in China

Choosing Flexo Inks: Water-based vs UV vs Solvent

OEM/ODM flexo printer slotter die-cutter stacker machine Manufacturers and supplier

Industry Solutions

How can your folding carton machines benefit my packaging business?

Our machines increase production efficiency, reduce labor costs, and ensure high-quality, consistent carton production.

Product

What maintenance is required for optimal machine performance?

Regular lubrication, cleaning of the folding units, and checking for worn parts are essential for maintaining optimal performance.

Do your machines support automated quality control checks?

Yes, our machines can be equipped with automated quality control systems to ensure consistent production quality.

How do I adjust the machine settings for different carton sizes?

Machine settings can be adjusted using the intuitive control panel, which allows for quick changes to accommodate different carton sizes.

Shipping

How are your machines packaged for safe transportation?

Our machines are securely packaged using high-quality materials to prevent damage during transit.

Shinko Super Alpha Movable Type Full Servo Drive Flexo Printing Slotting Die Cutting Inline Folding Gluing Counting Ejecting Machine

This state-of-the-art Movable Type Full Servo Drive Flexo Printing Slotting Die Cutting Machine streamlines your production with precision. Experience seamless operation with its Inline Folding Gluing Counting Ejecting capabilities, ensuring unparalleled efficiency. Designed for high-performance tasks, this Keshenglong&Shinko Super Alpha Movable Type Full Servo Drive Flexo Printing Slotting Die Cutting Inline Folding Gluing Counting Ejecting Machine enhances productivity while maintaining premium quality. Ideal for businesses seeking innovation and reliability, the Shinko Super Alpha is your go-to solution for advanced printing and cutting needs.

Computerized Flexo Printing Slotting Die-Cutting Inline Folding Gluing and Stitching Machine

Introducing the Keshenglong&Shinko Computerized Flexo Printing Slotting Die-Cutting Inline Folding Gluing and Stitching Machine, a pinnacle of precision and efficiency. This state-of-the-art machine revolutionizes packaging production with seamless integration of printing, slotting, die-cutting, folding, gluing, and stitching. Designed to optimize your workflow, the Computerized Flexo Printing Slotting Die-Cutting Machine enhances accuracy and productivity.

Computerized Flexo Top Bottom Printing Slotting Die-Cutting Machine

Introducing the Keshenglong&Shinko Computerized Flexo Top Bottom Printing Slotting Die-Cutting Machine, designed to enhance your packaging efficiency. Engineered for precision, this high-performance machine offers seamless integration of flexo printing and die-cutting processes. Perfect for a variety for packaging needs, it ensures superior quality and productivity. With user-friendly controls and robust construction, it guarantees reliable operation and minimal downtime. Optimize your production line with Keshenglong’s trusted technology. Explore advanced capabilities with our Flexo Top Bottom Printing Slotting Die-Cutting Machine today.

Computerized Flexo Printing Slotting Die-Cutting Inline Folding Gluing Countering Ejecting Machine Repeatable

Introducing the Keshenglong Computerized Flexo Printing Slotting Die-Cutting Inline Folding Gluing Countering Ejecting Machine. This advanced equipment delivers precision and efficiency for all your packaging needs. Perfectly designed for high-speed operations, it ensures seamless integration with your production line. Enhance productivity with our innovative technology that guarantees accurate printing, slotting, and die-cutting.

© 2025 Keshenglong & SHINKO All Rights Reserved.

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine