Flexo inks explained: Water-based, UV and solvent inks

- Understanding Ink Choices for Corrugated Flexo Printing

- Why ink choice matters for your flexo printer

- What packaging stakeholders want to know about flexo printer inks

- Overview of flexo ink types: water-based, UV, and solvent

- Water-based inks for flexo printer corrugated lines

- UV-curable inks for high-speed flexo printer applications

- Solvent-based inks: traditional choice with trade-offs

- Side-by-side technical comparison

- Operational considerations for specifying inks with your flexo printer

- Line layout: inline vs offline converting

- Drying infrastructure and energy use

- Regulatory and sustainability requirements

- Quality trade-offs: print fidelity, spot colors and varnishes

- Achieving consistent spot colors on corrugated with a flexo printer

- Varnishes and protective overprints

- Cost-to-performance analysis for buyers of flexo printer equipment

- Total cost of ownership (TCO) factors

- Example: simplified cost drivers (illustrative)

- Keshenglong & Shinko: integrated supplier context for corrugated flexo printing

- Keshenglong & Shinko advantages for buyers of flexo printer systems

- Main products matching ink-system decisions

- Recommendations: selecting ink for your flexo printer production goals

- If your priority is speed and immediate converting

- If your priority is low VOCs and simple operations

- If your priority is substrate versatility and wetting

- Implementation checklist for printing managers

- Conclusion

- FAQs

- 1. Which ink type is best for corrugated boxes printed on a flexo printer?

- 2. Can I switch my existing flexo printer from solvent inks to water-based or UV?

- 3. How do VOC regulations affect ink choice for flexo printers?

- 4. Do UV inks harm corrugated board strength or recyclability?

- 5. Are LED UV lamps better than traditional mercury lamps for flexo printing?

- 6. How should I evaluate ink consumption and color consistency for a new flexo printer?

- Contact and product inquiry

Understanding Ink Choices for Corrugated Flexo Printing

Why ink choice matters for your flexo printer

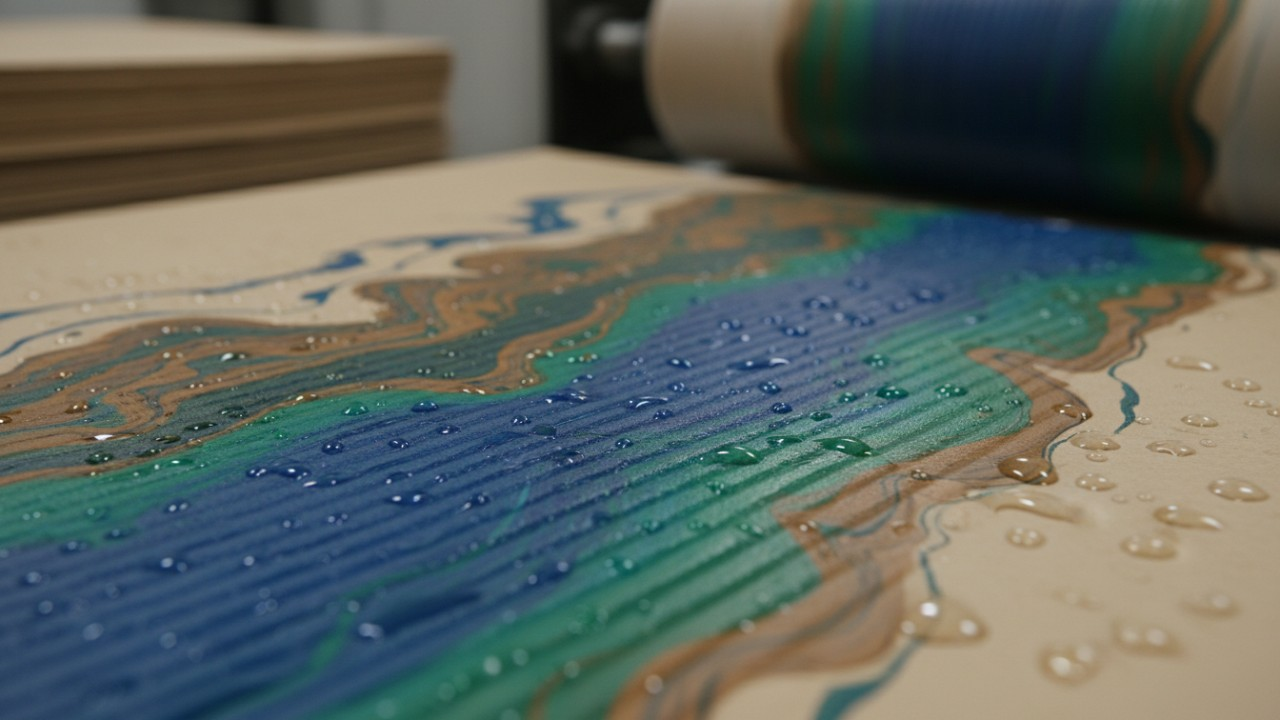

When specifying a flexo printer for corrugated carton production, selecting the right ink system is as important as the press itself. Ink affects print quality, run speed, curing/drying equipment requirements, substrate compatibility, regulatory compliance (especially VOCs), and total cost of ownership. Choosing between water-based, UV-curable, and solvent-based inks directly impacts a packaging line’s throughput, maintenance, and sustainability profile.

What packaging stakeholders want to know about flexo printer inks

Decision-makers typically ask: Which ink gives the best color and speed on single-wall and double-wall corrugated board? How does each ink affect machine uptime and consumable costs? What are the environmental, health and regulatory implications? This article answers those questions with actionable comparisons, process implications and vendor guidance for buyers of flexo printers and integrated printing-slotting die-cutting machines.

Overview of flexo ink types: water-based, UV, and solvent

Water-based inks for flexo printer corrugated lines

Water-based (WB) inks use water as the primary carrier. They are widely used for corrugated printing because they are lower in volatile organic compounds (VOCs) and generally easier to clean than solvent systems. WB inks rely on water evaporation and absorption into the board liner; drying systems (hot air, infrared or combination) are required to achieve full set on high-speed presses.

UV-curable inks for high-speed flexo printer applications

UV-curable inks are formulated with oligomers, monomers and photoinitiators that polymerize instantly when exposed to UV light. Because curing is near-instant, UV inks enable higher press speeds and immediate downstream converting (slotting/die-cutting/stacking) without waiting for evaporation. They tend to produce vibrant colors and high rub resistance but require UV lamps (LED or mercury) and rigorous safety measures for photoinitiator handling and worker exposure.

Solvent-based inks: traditional choice with trade-offs

Solvent-based inks use organic solvents to carry pigments. They dry as the solvent evaporates. Historically favored for their strong wetting and ink transfer characteristics, solvent inks deliver robustness on difficult substrates and fast set times with appropriate dryers. However, they come with higher VOC emissions, regulatory controls, and often higher operator safety requirements.

Side-by-side technical comparison

Below table summarizes measurable differences relevant to corrugated flexo printer operations. Data ranges are industry-typical; actual values vary by formulation and supplier.

| Attribute | Water-based inks | UV-curable inks | Solvent-based inks |

|---|---|---|---|

| Drying / curing | Evaporation and absorption; hot air/IR dryers needed | Instant UV polymerization (LED/Mercury lamps) | Evaporation; fast with powerful dryers |

| Typical VOC content | Low (near 0–3%) | Near 0% after cure; negligible emissions | High (can be 10–60% depending on solvent type) |

| Press speed potential | Moderate to high (depends on dryer capacity) | High (supports very high speeds due to instant cure) | High (with adequate drying equipment) |

| Color vibrancy & gloss | Good; often matte on uncoated corrugated | Excellent; high gloss and color depth possible | Good; can be formulated for high gloss |

| Adhesion on corrugated board | Good if board is absorbent; risk of set-off if not dried | Excellent adhesion on many substrates with primers | Excellent wetting and transfer |

| Downstream converting | May require waiting/auxiliary drying before slotting | Immediate converting—advantageous for inline flexo slotting die-cutting | Requires drying; careful handling to avoid contamination |

| Operator safety & environment | Lower health risks; water cleanup | Manage photoinitiator and ozone; generally low VOC | Higher worker exposure risks; require ventilation & controls |

| Typical cost (ink only) | Low to moderate | Moderate to high | Moderate; solvent recovery adds cost |

Sources: industry summaries and regulatory guidance (see references).

Operational considerations for specifying inks with your flexo printer

Line layout: inline vs offline converting

If your investment is an inline flexo printer-slotting die-cutting machine (for example flexo printing slotting die-cutting and stacker lines), UV-curable inks can be a strong choice because they enable immediate converting and stacking. Water-based lines require larger drying modules and sometimes a separate cooling/conditioning section before die-cutting to avoid set-off or poor die-cut quality.

Drying infrastructure and energy use

Water-based and solvent systems demand robust drying tunnels—this increases energy use and floor space. UV systems shift cost toward UV lamps and shielding but reduce drying tunnel length. Consider total lifecycle energy and capital cost when selecting ink type for a new flexo printer installation.

Regulatory and sustainability requirements

Many markets incentivize low-VOC operations. For supply chains requiring eco-labels or compliance with stringent VOC limits, water-based or UV inks are preferred. Solvent inks may require VOC control systems (thermal oxidizers or recovery units), increasing CAPEX and OPEX.

Quality trade-offs: print fidelity, spot colors and varnishes

Achieving consistent spot colors on corrugated with a flexo printer

UV inks usually reproduce spot colors with higher chroma due to higher pigment loading and less absorption. Water-based inks can appear duller on uncoated corrugated because pigments are absorbed into the board. Solutions include barrier coatings or primers to improve color pop when using water-based or solvent inks.

Varnishes and protective overprints

UV overprint varnishes offer excellent scuff resistance and are often used in high-end packaging. Water-based varnishes can be effective but may require drying and careful compatibility checks. Solvent-based varnishes perform well but carry VOC penalties.

Cost-to-performance analysis for buyers of flexo printer equipment

Total cost of ownership (TCO) factors

When comparing ink systems, evaluate: ink cost per m2, energy/dryer costs, ventilation and VOC controls, downtime for cleaning, waste treatment, and yield (rejects due to poor adhesion or set-off). UV systems may have higher ink costs but lower drying energy and faster throughput, improving productivity. Solvent systems may require more investment in emission controls. Water-based systems can be lowest ink cost but require space and energy for drying and sometimes slower throughput.

Example: simplified cost drivers (illustrative)

Consider a 100,000 m2/month production line. If UV curing reduces process time and enables an extra shift-equivalent throughput, the incremental productivity gain can offset higher ink prices. Actual ROI calculations should use supplier-specific ink consumption (g/m2), local energy prices and regulatory compliance costs.

Keshenglong & Shinko: integrated supplier context for corrugated flexo printing

Founded in 1995, Keshenglong is specialized in manufacturing corrugated carton printing machines and packaging solutions. The company’s product portfolio includes flexo printers and computerized high-speed Flexo Slotting Die-Cutting machines (1-6 color), computerized high-speed Flexo case makers, 6+1 high-precision Precision Printing Slotting Die-Cutting machines, Top & Bottom Printing Slotting Die-Cutting machines, and jumbo-size Flexo Printing Slotting Die-Cutting machines. In 2017 Keshenglong merged with Japan's Shinko, retaining Shinko as the R&D center and production base while establishing an additional production base in Guangzhou, China. Key components are imported from Japan and installations are instructed by experienced Japanese technicians to maintain quality on par with Japan Shinko standards. As a supplier of integrated intelligent packaging solutions, Keshenglong's products have been exported to more than 70 countries.

Keshenglong & Shinko advantages for buyers of flexo printer systems

Keshenglong’s combined strengths with Shinko include: Japanese R&D and quality standards, imported critical components, on-site Japanese-led installation and testing, and a product line optimized for corrugated carton applications—especially inline flexo printing slotting die-cutting and stacking machines. For buyers seeking integrated solutions (printing + slotting + stacker) that support rapid converting—particularly when using UV-curable inks—the Keshenglong & Shinko lineup reduces vendor coordination risk and accelerates commissioning.

Main products matching ink-system decisions

- Corrugated carton flexo printing machine — configurable for water-based or UV inks, with modular dryer/UV station options.

- Flexo printing slotting die-cutting machine — ideal for inline workflows; UV curing reduces waiting before slotting.

- Flexo printing slotting die-cutting and stacker machine — integrated line for immediate stacking and shipping.

- High-speed Flexo case makers and precision slotting machines — for large-volume, high-precision runs.

Recommendations: selecting ink for your flexo printer production goals

If your priority is speed and immediate converting

Choose UV-curable inks and equip the flexo printer with UV (preferably LED) curing stations. This combination minimizes footprint for drying tunnels and supports high-speed inline slotting die-cutting and stacking.

If your priority is low VOCs and simple operations

Water-based inks are generally the best balance—lower regulatory burden and easier cleanup. Ensure adequate drying capacity and consider pre-treatment or primers for improved color and adhesion on certain corrugated boards.

If your priority is substrate versatility and wetting

Solvent-based inks still have a role where very difficult substrates or specific gloss/adhesion characteristics are required, but plan for VOC abatement and stricter safety measures.

Implementation checklist for printing managers

- Define product mix (single-color vs multi-color, graphics intensity).

- Evaluate inline vs offline converting; factor in curing/drying needs.

- Request ink consumption (g/m2) and recommended dryers/UV specs from ink suppliers.

- Plan for ventilation, VOC control or UV safety enclosures as needed.

- Run trial production on representative board stocks with target ink systems.

- Calculate TCO including ink, energy, emissions control, maintenance and potential yield improvements.

-

Conclusion

- Choosing the right flexo ink—water-based, UV, or solvent—is vital for corrugated production. This guide compares their impact on speed, quality, and VOC compliance. It highlights how Keshenglong & Shinko’s integrated machines optimize these ink systems to enhance throughput, sustainability, and total cost of ownership for packaging stakeholders.

FAQs

1. Which ink type is best for corrugated boxes printed on a flexo printer?

There is no single “best” ink—choice depends on priorities. For fastest throughput and immediate converting, UV-curable inks are preferred. For lower VOCs and simpler safety, water-based inks work well. Solvent inks are chosen for specific adhesion or drying needs but have higher regulatory burdens.

2. Can I switch my existing flexo printer from solvent inks to water-based or UV?

Possibly, but it depends on press configuration. Switching to water-based may require additional or reconfigured drying systems. Switching to UV requires installing UV curing units (LED or mercury) and ensuring press inks and aniloxes are compatible. Trials and supplier consultation are essential.

3. How do VOC regulations affect ink choice for flexo printers?

Many regions limit VOC emissions from printing operations. If regulations are strict, water-based or UV systems usually face fewer constraints. Solvent-based operations may require VOC capture and control systems, adding cost and permitting complexity.

4. Do UV inks harm corrugated board strength or recyclability?

Properly formulated UV inks generally do not significantly affect board strength. Recyclability can be impacted by certain additives; work with ink and recycling partners to ensure compatibility with local carton recycling streams.

5. Are LED UV lamps better than traditional mercury lamps for flexo printing?

LED UV lamps offer energy efficiency, longer lamp life and reduced ozone generation compared with mercury lamps. However, LED systems require inks formulated for LED wavelengths. Many suppliers now offer LED-curable ink options optimized for flexo applications.

6. How should I evaluate ink consumption and color consistency for a new flexo printer?

Ask ink suppliers for documented consumption metrics (g/m2) for your substrate and color targets. Run press trials with your anilox rolls and print screens. Implement color management systems and spectrophotometer checks to ensure consistency across shifts and presses.

Contact and product inquiry

If you are evaluating flexo printer solutions, drying/curing options, or integrated inline flexo printing-slotting-die-cutting lines, contact Keshenglong for technical consultation, demo trials and quotes. View products and request customized solutions for corrugated box production: info@keshenglong.com or visit the product page to see corrugated carton flexo printing machines, flexo printing slotting die-cutting machines and integrated stacker lines.

Top flexo printing machine for corrugated carton Manufacturers and suppliers

Corrugated Carton Flexo Printing Machine Insights: Keshenglong&Shinko

Top odm corrugated box printing machine Manufacturers and Suppliers in us

The flexo machine printing Cost Guide

Industry Solutions

How can your machines improve my production workflow?

By automating carton production, our machines streamline your workflow, increase output, and reduce downtime.

Do you offer customized solutions for unique production needs?

Yes, we work closely with clients to develop customized solutions that meet their specific production requirements.

What kind of technical support do you offer for industry applications?

We provide comprehensive technical support, including installation, maintenance, and troubleshooting services.

Product

What maintenance is required for optimal machine performance?

Regular lubrication, cleaning of the folding units, and checking for worn parts are essential for maintaining optimal performance.

How do I troubleshoot common issues with the folding mechanism?

Common issues can often be resolved by checking the alignment of the folding plates and ensuring there is no debris obstructing the mechanism.

Computerzied Semi Auto Flexo Printing Slotting Die-Cutting Machine

Shinko Super Alpha Movable Type Full Servo Drive Flexo Printing Slotting Die Cutting Inline Folding Gluing Counting Ejecting Machine

This state-of-the-art Movable Type Full Servo Drive Flexo Printing Slotting Die Cutting Machine streamlines your production with precision. Experience seamless operation with its Inline Folding Gluing Counting Ejecting capabilities, ensuring unparalleled efficiency. Designed for high-performance tasks, this Keshenglong&Shinko Super Alpha Movable Type Full Servo Drive Flexo Printing Slotting Die Cutting Inline Folding Gluing Counting Ejecting Machine enhances productivity while maintaining premium quality. Ideal for businesses seeking innovation and reliability, the Shinko Super Alpha is your go-to solution for advanced printing and cutting needs.

Computerized Flexo Printing Slotting Die-Cutting Inline Folding Gluing and Stitching Machine

Introducing the Keshenglong&Shinko Computerized Flexo Printing Slotting Die-Cutting Inline Folding Gluing and Stitching Machine, a pinnacle of precision and efficiency. This state-of-the-art machine revolutionizes packaging production with seamless integration of printing, slotting, die-cutting, folding, gluing, and stitching. Designed to optimize your workflow, the Computerized Flexo Printing Slotting Die-Cutting Machine enhances accuracy and productivity.

Computerized Flexo Top Bottom Printing Slotting Die-Cutting Machine

Introducing the Keshenglong&Shinko Computerized Flexo Top Bottom Printing Slotting Die-Cutting Machine, designed to enhance your packaging efficiency. Engineered for precision, this high-performance machine offers seamless integration of flexo printing and die-cutting processes. Perfect for a variety for packaging needs, it ensures superior quality and productivity. With user-friendly controls and robust construction, it guarantees reliable operation and minimal downtime. Optimize your production line with Keshenglong’s trusted technology. Explore advanced capabilities with our Flexo Top Bottom Printing Slotting Die-Cutting Machine today.

© 2025 Keshenglong & SHINKO All Rights Reserved.

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine

Keshenglong Carton Packing Machine